On This Page:

Energy LeadershipEnergy for a Cleaner Environment

Energy for Modern Life

Energy for the Future

Policy Pathways

We Are America’s Generation Energy

Energy Leadership

The United States is the world’s leading natural gas and oil producer and refiner. That energy leadership means America is stronger, more secure and more prosperous.

This Is Energy Leadership

Through ever-advancing technology and 21st-century innovation, the natural gas and oil industry provides the energy that has made the United States the world’s leading producer and refiner – both of which are foundational to American energy leadership in the world. Today’s natural gas and oil industry is invested in the brainpower, engineering and scientific initiatives that are developing reserves safely and efficiently so that the U.S. can fully harness the power of American energy.

“Despite the progress we made over the last five years we ought to see that move exponentially again over the next five and 10 years.”

– Ryan Lance, ConocoPhillips chairman and CEO

Lowest Net Imports Of Petroleum In More Than 50 Years

Thanks to U.S. global leadership in natural gas and oil production, petroleum imports (crude oil and refined products) are at their lowest level since the 1960s. Americans can look to the future from a position of energy strength – more self-sufficient, energy secure and able to provide leadership around the world, helping friends and deterring adversaries.

10.3 Million Jobs

The natural gas and oil industry supports 10.3 million jobs across the economy. This includes hundreds of thousands of well-paying jobs using cutting-edge technologies. Our industry is driving broad economic growth that benefits millions of Americans with greater opportunity and freedom to thrive.

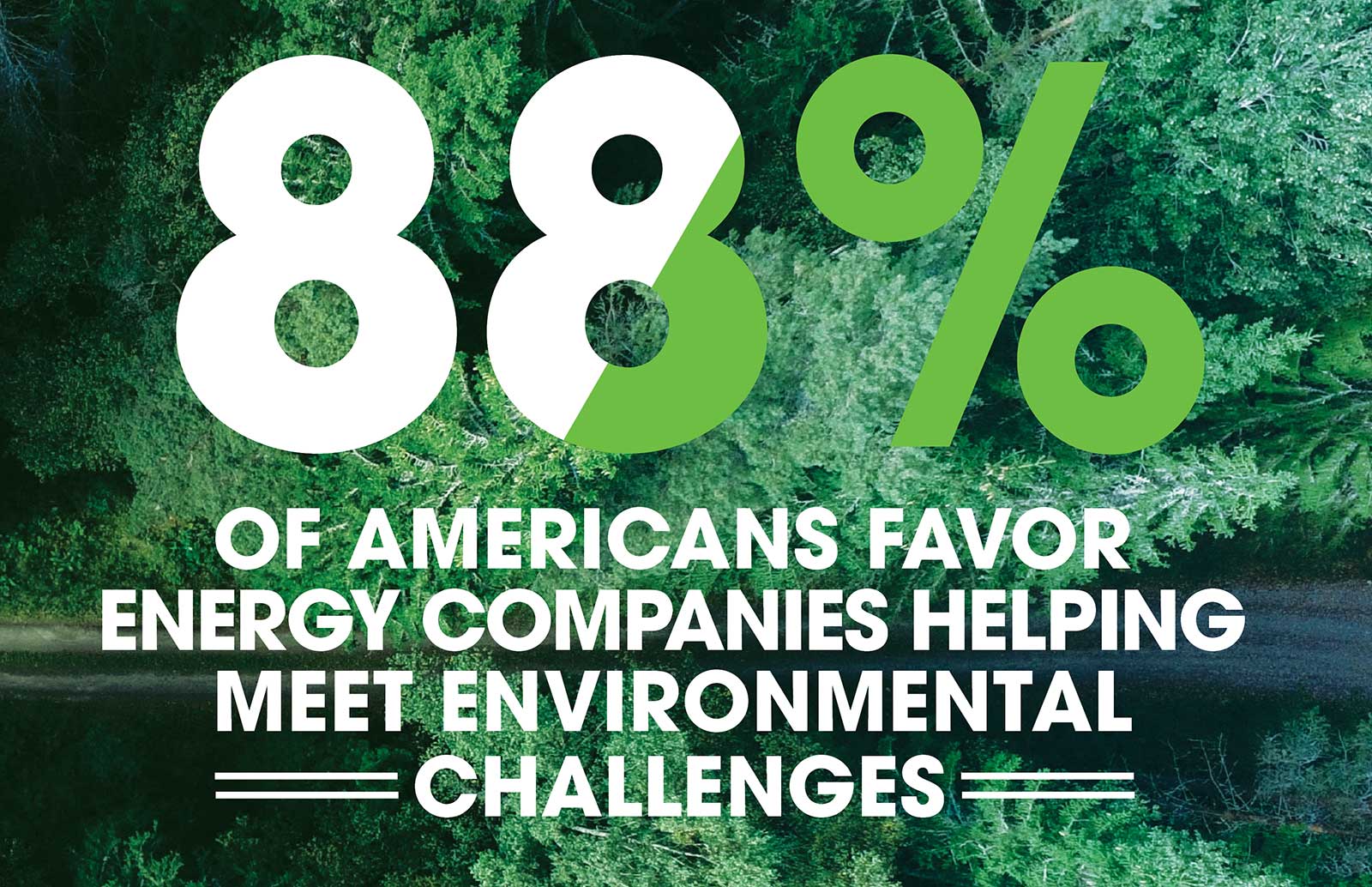

World Leader In Reducing CO2

No nation on earth has reduced carbon dioxide emissions as much as the U.S. since 2005. Our CO2 emissions have fallen to their lowest level in 25 years – largely because of increased use of clean natural gas – while the rest of the world’s CO2 emissions have risen 50 percent since 1990.

Energy Leadership By The Numbers

Barrels of U.S. Oil Produced Per Day (2018 10-month average) – more than double levels a decade ago

Net U.S. petroleum imports lowered by 70% since 2005 due to domestic production

Cubic feet per day of U.S. natural gas and natural gas liquids marketed production making the U.S. the world’s top producer in 2018

Energy For A Cleaner Environment

Energy is fundamental to the lives we want to live – free, safe and healthy, with broad opportunity. Delivering the natural gas and oil that powers and supports modern living means doing so with lower emissions and improved products and operations. In all of these, industry is helping lead the way.

This Is Energy For A Cleaner Environment

Cleaner operations, facilities and products – all are part of the natural gas and oil industry’s commitment to improve its environmental performance and accelerate society’s climate goals while producing the energy required by a modern economy. Developing natural gas and oil is an industrial process, yet its impacts can be managed using advanced technologies to protect the environment, our workers and the communities that host our operations.

For example, industry is highly motivated to use a variety of technologies to capture more and more methane during production that can be delivered to consumers as natural gas. Increased use of natural gas to fuel power generation is the No. 1 reason U.S. emissions of carbon dioxide have fallen to levels not seen in more than two decades.

“ We’re commited to doing our part.”

– Vicki Hollub, Occidental Petroleum President and CEO

99% Fewer Vehicle Emissions

U.S. refiners are producing cleaner gasoline and diesel fuels which, coupled with advanced vehicle technologies, means today’s new cars, SUVs and pickup trucks are about 99 percent cleaner for common pollutants than vehicles in 1970. Cleaner fuels played a significant role in a 73 percent reduction of the six Clean Air Act Criteria Air Pollutants between 1970 and 2017 – even as vehicle miles traveled increased 189 percent.

Cleanest Air In More Than A Decade

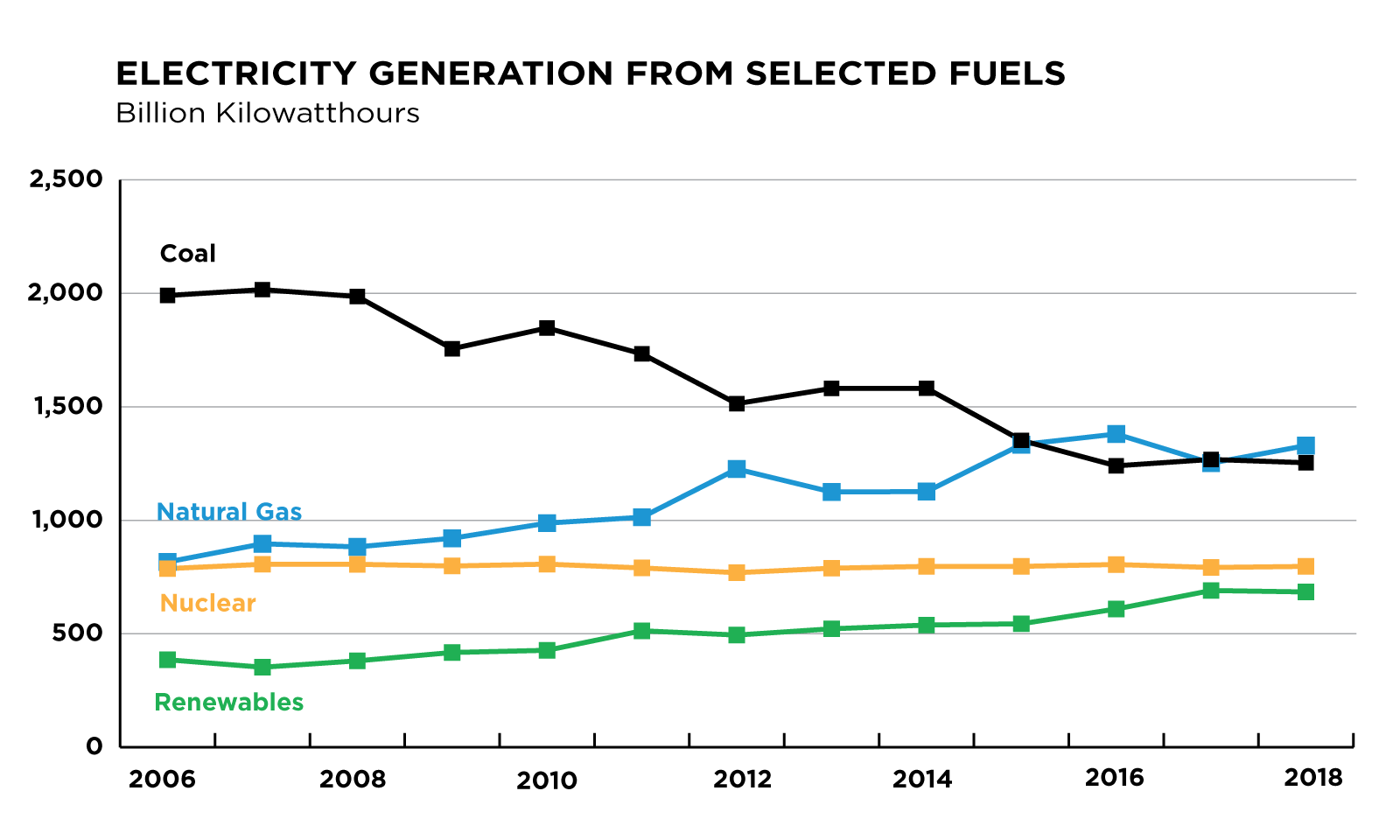

The increased use of clean natural gas in generating the nation’s electricity – in many cases replacing coal-fired generation – is the leading reason the air Americans breathe is cleaner today than it has been since the the turn of the century.

Methane Emissions By Natural Gas Systems Down 16%

Technologies – including more advanced leak detection equipment – helped decrease methane emissions from natural gas systems 16 percent since 1990 while natural gas production increased more than 50 percent. The Environmental Partnership is helping galvanize the continuing effort to reduce methane emissions through learnings and collaboration.

A Cleaner Environment By The Numbers

Natural gas is the primary reason the U.S. leads the world in cutting carbon dioxide emissions while global emissions are up

The reduction in U.S. air pollutants between 1970 and 2016, thanks in large part to cleaner fuels and more efficient engines

Energy For Modern Life

Natural gas and oil are integral in all parts of our modern lives – every hour, every day. They power and support our transportation and 21st-century electricity grid while making possible so many products that make life easier, healthier and safer.

This Is Energy For Modern Life

America’s energy abundance has produced lower energy costs for consumers and increased household disposable income. The reliability and availability of natural gas allows it to be the essential partner for the grid integration of intermittent renewable energies such as wind and solar.

Our industry is constantly working to develop cleaner fuels for the transportation sector of today and tomorrow. Meanwhile, data-assisted, technologically advanced well construction is safely unlocking vast deposits of natural gas and oil with an ever-smaller footprint.

“Energy underpins modern society.”

– Darren Woods, ExxonMobil Chairman and CEO

68% Of U.S. Energy From Natural Gas & Oil

Natural gas and oil provide power that is essential in Americans’ daily lives. Natural gas heats homes, prepares meals and fuels generation of a third of our electricity. Oil powers transportation, ensuring freedom of movement and supporting the broader economy. No other energy source can match natural gas and oil for reliability and consistency across a nation as large as the United States.

32% Of U.S. Electricity From Natural Gas

Natural gas is the leading fuel for U.S. electricity generation because it is abundant, affordable and reliable. Clean natural gas furnishes many attributes needed for a healthy electricity grid – quick ramp-up ability and capable of cycling on and off rapidly to meet changing levels of load due to increasing use of variable renewable energy on the grid. Natural gas long has provided reliable and continuous supplies to customers – including under adverse conditions.

The Products We Use – From A-Z

Natural gas and oil are present in virtually everything that makes modern life possible – as the building blocks for products and components associated with health care, clean water, education, entertainment, communications, art, agriculture and more – powering and supporting all of us.

Modern Life By The Numbers

To states, communities and American Indian tribes for education, infrastructure, conservation and other projects – from revenues generated by energy and minerals production in federal areas

Of U.S. power estimated to come from natural gas in 2040 in EIA’s high resource/technology case

Energy For The Future

The future belongs to those who have access to energy – secure, abundant energy. Natural gas and oil are the leading energies to grow our economy and to help keep our country safe, today and tomorrow.

Our well-being as a society is directly linked to the energy to grow, invent and meet challenges of all kinds.

This Is Energy For The Future

The natural gas and oil industry is a leader in using advanced technologies, helping the nation capitalize on its domestic energy abundance – even as the country looks to an all-of-the-above energy future in which natural gas and oil partner with renewables.

Natural gas and oil are unsurpassed in the attributes that power a modern society, including portability and reliability. This is why energy forecasters project an energy future in which natural gas and oil continue to be leaders, here at home and around the world.

With the right policies, natural gas and oil can continue to power a modern economy while also providing economic lift of its own by creating jobs that pay well, capital investment and associated spending by companies and their employees throughout the economy. At the same time, industry is focused on its workforce of the future, creating more career opportunities for women, minorities and Millennials. The natural gas and oil industry values diverse perspectives and contributions as key to driving continued innovation in the energy space.

“Technology is really the heart and soul of our business, and really our industry.” – Jeff Miller, Halliburton CEO

Petroleum – The Best Energy There Is

Oil is energy rich and portable – valuable qualities for powering a modern economy. Natural gas and oil are adaptable and integral as feedstocks for an array of other products and technologies, ensuring their vital role for years to come.

2040: 66.6% Of U.S. Energy From Natural Gas & Oil

The U.S. Energy Information Administration, the International Energy Agency and other agencies project that natural gas and oil – today’s leading fuels at home and around the world – will be the leading fuels for decades to come.

2035: Well Over A Million More Jobs Supported

Pro-development policies could increase the total number of U.S. jobs supported by natural gas and oil by 1 million in 2025 and more than 2.3 million in 2035. Industry drives broad economic growth through its own jobs, its spending in associated sectors and through the personal spending of industry workers.

Energy For The Future By The Numbers

U.S. jobs supported by natural gas and oil

in private natural gas & oil infrastructure investment is possible out to 2035

In 2017, jobs in natural gas and oil extraction had an average salary of $165,670 nearly 3x the national average of $55,330

Policy Pathways

The natural gas and oil industry is focused on increasing energy production while also accelerating efforts to reduce emissions associated with a process that’s industrial in nature. To those ends, industry works with state and federal governments and other authorities to develop effective energy policies and regulations that support safe and responsible natural gas and oil production – to benefit the economy, U.S. security, the environment and the American people.

Energy policy must be forward-looking and help harness vast U.S. natural gas and oil reserves. Smart and effective regulation must include clear, common sense rules that consider industry’s innovation, advanced technologies and experience, as well as its demonstrated commitment to setting useful standards for operations, equipment and workers. All of these have strengthened industry’s safety culture.

The following pages describe the pathways to sound energy policy, smarter and more effective regulation of industry operations, onshore and offshore – all for managing the safe energy development America needs today and well into the future.

Expand Offshore And Onshore Access

- 94% of offshore federal acreage is off limits to development

- The United States is the World’s No.1 producer of natural gas and oil

The federal government should implement a robust, strategic offshore natural gas and oil leasing program to lay the foundation for critical production that will underpin America’s energy security for decades to come, while streamlining review and permitting processes to facilitate onshore development. Increasing access to the nation’s natural gas and oil reserves is vital to meeting the country’s energy needs. Offshore natural gas and oil reserves can take a decade or more to develop, so access now will help secure continued growth in the future. Expanded access increases production that promotes economic growth, generating hundreds of thousands of well-paying jobs and billions of dollars in revenues to governments.

Accelerate Emissions Reductions And Climate Progress

- 75% of Americans support the role natural gas is playing in reducing greenhouse gas emissions.

The natural gas and oil industry continues to address the significant risks of climate change – while also producing, delivering and refining natural gas and oil to power a growing economy. The United States has shown that climate and environmental progress occurs simultaneously with a growing economy and increased energy production.

The increased use of natural gas, cleaner fuels and new, efficient technologies have enabled the United States to lead the world in lowering emissions of carbon dioxide – even as these emissions have increased 50 percent elsewhere around the globe since 1990. Progress in reducing emissions can continue with a common sense approach that acknowledges the contributions made by advanced industry technologies, innovations and initiatives such as The Environmental Partnership.

The partnership includes more than 50 natural gas and oil companies that are focused on accelerating reductions in methane emissions through: shared learning about the latest industry innovations and best practices; working together to achieve improved environmental performance; and taking action with specific programs, based on EPA emissions data, that use proven, cost-effective technologies to further reduce emissions of methane and volatile organic compounds.

Build More Energy Infrastructure

- Promoting energy infrastructure across the nation could support 1 million jobs per year through 2035

- $1.89 trillion could be added to the U.S. economy between 2017 and 2035

- 84% of Americans support increased development of the country’s energy infrastructure.

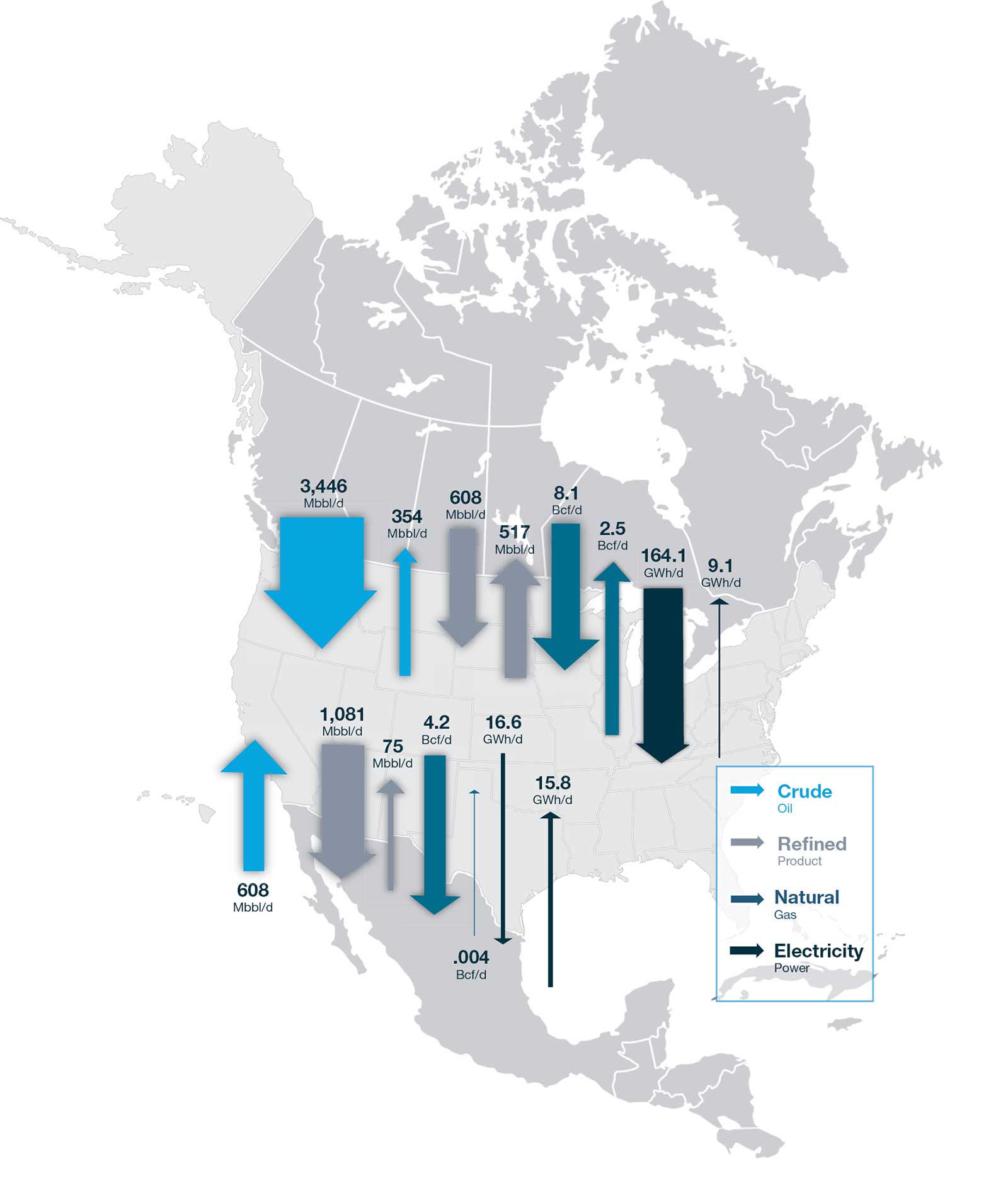

U.S. energy infrastructure is an arterial network of pipelines, rail systems, storage tanks, export terminals, ports and waterways that delivers natural gas and oil from production zones to refining and processing centers, and then to consumers.

The U.S. pipeline network spans 2.7 million miles, yet some parts of the country remain under-served. So new or expanded capacity is needed to ensure that Americans in all regions may benefit from the nation’s natural gas and oil wealth.

Infrastructure development – including the development and maintenance of rail and marine infrastructure – supports good jobs, economic growth and U.S. security. Increasing efficiency, transparency and the certainty in federal permitting is important to align needed oversight with responsible and timely action on needed projects.

Ensure Fair Access To Power Markets For Natural Gas

- Natural gas is the leading fuel source of U.S. electricity

Markets, not government interventions, should determine energy sources for power generation. They reward innovation, work toward lower prices, reduce emissions in the power sector and benefit consumers. Because of natural gas’ abundance and flexibility, it is increasingly the fuel of choice for generating electricity. Markets should be allowed to function freely, without government putting its thumb on the scales. The increased use of natural gas has enhanced the reliability of the power system overall. Natural gas’ resilience has been demonstrated in the face of extreme weather events and other direct impacts. Clean natural gas is responsible for about 60 percent of the reductions in carbon dioxide emissions that have resulted from changes in the power sector’s fuel mix since 2005.

Source: U.S. Energy Information Administration.

Source: U.S. Energy Information Administration.

Open Global Markets For U.S. Natural Gas & Oil Exports

- Record U.S. liquid petroleum exports totaled 7.8 million barrels per day in June/July 2018

- Record U.S. natural gas exports totaled 10 billion cubic feet per day in August 2018

As the world leader in the production and processing of natural gas and oil, the United States can meet the needs of a growing domestic economy and also supply energy to friends and allies around the globe. Thanks to surging natural gas and oil production here at home, the U.S. is a significant exporter of both crude oil and liquefied natural gas (LNG).

These exports strengthen America’s standing as a world energy superpower and are creating opportunities for the U.S. to use its energy for good around the world. Going forward, policies should support adding more LNG export capacity, which can help meet expected growth in global demand for natural gas. Policies also should facilitate increased U.S. energy exports – to boost trade, help spur domestic production and grow the economy.

Modernize And Strengthen Free Trade Agreements

- An integrated U.S.-Mexico-Canada energy market helps keep energy affordable for Americans

Free trade agreements – eliminating tariffs, creating energy trading zones and protecting U.S. energy investments in other countries – help open markets for American natural gas and oil, boosting production and job growth in this country. Provisions in free trade agreements help create a level playing field for U.S. energy companies around the world, which is fundamental to the competitiveness of U.S. energy.

Congress should ratify the proposed U.S.-Mexico-Canada Agreement (USMCA) to help strengthen energy trading relationships between the three nations – which, under NAFTA (preceding USMCA) saw Canada and Mexico become the leading export markets for U.S. crude oil and a number of refined products including kerosene-type jet fuel and finished motor gasoline.

NOTE: Graphic is not scaled for energy content across different energy types

NOTE: Graphic is not scaled for energy content across different energy types

Sunset The Ethanol Mandate

- 74% of Americans agree that government regulation can increase the cost of gasoline for consumers

- Nearly 70% of vehicles on the road today are not designed to use E15

- 71% of Americans are concerned about government requirements that would increase ethanol in gasoline

The Renewable Fuel Standard (RFS) is outdated and broken, and its ethanol mandates can put consumers at risk. The program should be ended or significantly overhauled. In the interim, EPA should reduce the ethanol volumes required under the program.

The RFS’ objective of reducing crude oil imports has been made obsolete by surging domestic oil production. Its goal of launching commercially viable cellulosic biofuel production has not materialized. RFS mandates for increasing ethanol use in the nation’s fuel supply could impact consumers.

Gasoline demand in 2018 was 14 percent lower than was projected when the RFS was implemented more than a decade ago, which means there are fewer gallons available in which to blend ethanol. 33 As a result, more higher ethanol fuels, such as E15, could be forced into the fuel supply, potentially damaging vehicle engines.

Three out of four vehicles on the road today weren’t designed to use E15, based on manufacturers’ manuals. In addition, fuels with higher ethanol content can damage marine engines, motorcycle engines and outdoor power equipment.

Support Industry Cybersecurity Actions

Cybersecurity of the nation’s critical infrastructure is a top priority and industry takes seriously the responsibility to protect it, provide reliable energy for society and safeguard the public and environment. The cyber threats faced by industry are not unique to pipelines; they are prevalent across the energy system. Our companies recognize these threats and utilize a multidimensional approach to cybersecurity that incorporates high-level oversight and voluntary mechanisms including proven frameworks and public-private collaboration.

This performance-based approach, rather than prescriptive standards or regulations, is the best way to bolster the cybersecurity of industry companies and critical infrastructure. Government must recognize the limits of rigid mandates and guard against regulatory overreach and the imposition of rules that – in the world of information technology and cyber defense – quickly become obsolete as threats adapt and evolve.

“Our companies are providing the leadership, proactive solutions and ongoing coordination with federal agencies to help prevent future cyberattacks.”

– Mike Sommers, API President & CEO

We Are America’s Generation Energy

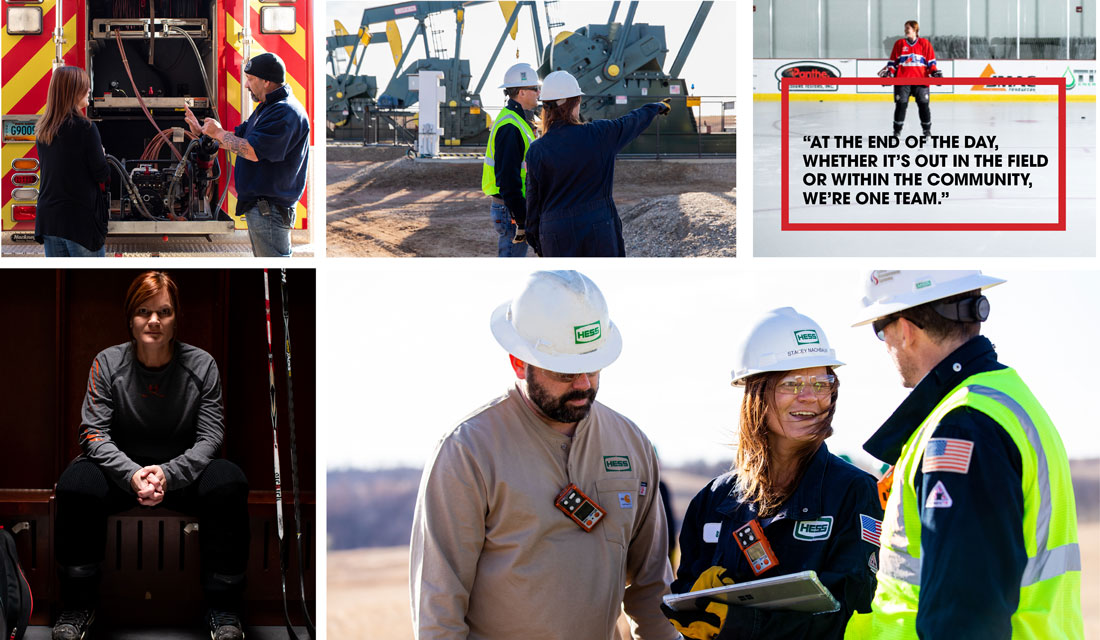

The people of the natural gas and oil industry are leaders in America’s Generation Energy. They live from one end of the U.S. to the other. We interviewed 13 of them for this report, to hear them talk about the importance of domestic energy, technology, science and an awareness that their work meets challenges much larger than themselves.

Hess’ Stacey Nachbaur is on point in the digital oil field.

Read More >>

Schlumberger’s Drew Pomerantz is helping industry capture methane.

Read More >>

Siemens’ Pratyush Nag is developing the latest turbine technology to amplify natural gas’ role in powering Americans’ lives.

Read More >>

Jennifer Osterhaus of BP is using technology to responsibly harness America’s deep water energy.

Read More >>

Data and technology help Devon Energy’s Alex Biholar pinpoint America’s energy treasures.

Read More >>

Through advanced cybersecurity, Chevron’s Marisa Ruffolo protects vital energy infrastructure.

Read More >>

Alyeska Pipeline’s Klint VanWingerden and cutting edge technologies keep the Trans Alaska flowing.

Read More >>

Jennifer Smith of Enbridge listens, engages and builds relationships – one handshake at a time.

Read More >>

Shell’s ‘Mac’ McLendon brings his own energy to protecting offshore workers and the environment.

Read More >>

Cheniere Energy’s Tyler Pedersen—on the frontier of exporting U.S. natural gas.

Read More >>

For ConocoPhillips’ Karen Work, Reusing Water is Key to Good Stewardship in the Permian Basin.

Read More >>

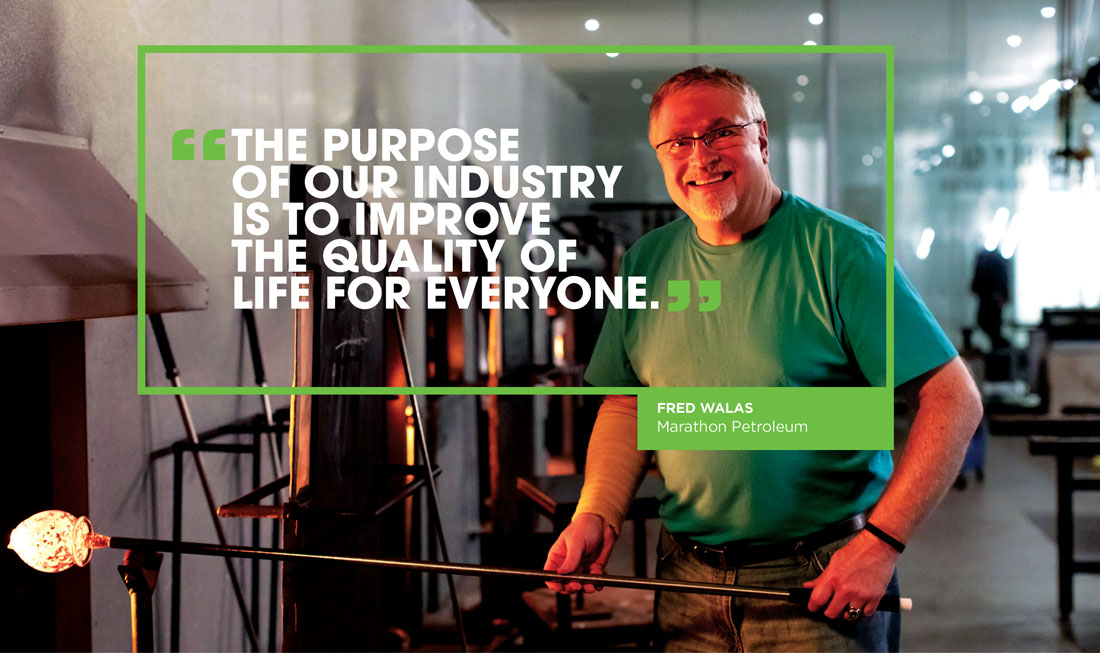

Marathon Petroleum’s Fred Walas finds art in the science of crafting fuels for today and tomorrow.

Read More >>

Mike Kerby of ExxonMobil believes technology is vital to solve energy and climate challenges.

Read More >>Maximizing U.S. Energy, Minimizing Its Footprint

Hess’ Stacey Nachbaur Is On Point In The Digital Oil Field.

Eight hockey pucks sit lined up like black buttons on the white ice, about 6 inches apart, just above the red hashmarks at one end of the rink inside the RoughRider Center in Watford City, North Dakota.

Suited out in her hockey gear, Hess’ Stacey Nachbaur eyes the closest one, gripping her stick, knees bent and skates about shoulder-width apart. The backswing of Stacey’s slapshot brings the stick’s blade above her head, and then she whips it through the puck, driving the shot toward the net. After the first one she cranks the others rapid-fire – the report of each shot echoing across the mostly vacant ice surface.

The same competitive fire that drove Stacey as an elite athlete during her college hockey career is an important part of her approach to managing Hess’ natural gas and oil production from thousands of wells across hundreds of miles throughout northern North Dakota. The leverage she applies to her booming slapshot serves as a metaphor for the leveraging of people, data and technology to drive timely, efficient energy production.

Stacey is part of America’s Generation Energy: integrating advanced technology and teamwork to develop the energy resources that power the U.S. economy and Americans’ modern lifestyles while also reducing her company’s physical and environmental footprint.

She and her skilled team of engineers, operators and technicians represent a 21st-century natural gas and oil industry, whose production has made the United States the world’s leading natural gas and oil nation, created jobs and prosperity from one coast to the other and powered a U.S. manufacturing renaissance. It’s technology-driven, smarter, safer and increasingly more efficient.

“We’re working in the digital oil field,” she says. “From the surface of the earth to underneath, technology is integral to protecting and enhancing production. It keeps all aspects of operation interconnected to improve safety, reduce our footprint and increase our productivity, and we have to be equipped to leverage the best of high-tech advancements to maintain our competitiveness in the global market.”

Like many in the industry, Stacey sees the evolution of a modern natural gas and oil industry. More than a decade ago, industry combined advanced hydraulic fracturing and horizontal drilling to launch the U.S. energy revolution, typified by surging production using less and less surface space – reduced by as much as 90 percent compared to years ago.

Last year, U.S. crude oil production was on track to reach 10.9 million barrels per day – more than doubling output levels from the previous decade, according to the U.S. Energy Information Administration.35 EIA also projected that the U.S. would see record year-end dry natural gas production of 83.3 billion cubic feet per day and natural gas liquids production of 4.3 million barrels per day.

The Bakken shale play that covers the northwest quadrant of North Dakota and the northeast corner of Montana is where much of this production is happening. When Stacey joined Hess in 2010, the company produced 15,000 barrels of oil equivalent per day in the Bakken. Today, that number is closer to 118,000 barrels per day.

“You can see anywhere from 12 to 20 wells on a single pad today,” she says. “We’re increasing production while reducing the environmental footprint of operations.”

Stacey’s team uses exception-based surveillance technologies to maximize efficiency and safety. They analyze automated data-collection to assess pressures, flow rates, temperatures and other information from the field. These systems combine data points with production accounting information and enterprise-wide analytics to create signals that keep teams aware of the performance of every well. This enables her team to identify and prioritize wells for checks by workers – to better problem solve and optimize performance.

Technology also has revolutionized drilling. “Walking rigs” – fully assembled drill rigs that can move from one well to the next without being disassembled in between – let operators complete multi-well pads more quickly.

Stacey says the continuous integration of new technologies across the industry requires professionals to be nimble and flexible. A willingness to listen, learn and adapt for improvement is also why Hess is a trusted energy partner within the communities in which it operates. In addition to managing production operations, Stacey also serves on the company’s community liaison team within the region. In 2018 alone, Hess supported over 40 local community organizations across North Dakota and in the past five years has invested approximately $30 million on community initiatives to strengthen education, workforce development, health and human services as well as support disaster relief.

“We’re very much a part of the communities and we’re committed to donating our time and services whenever we can. These are the communities where our employees live. It’s where we see our friends and neighbors. We’re producing safe and reliable energy. We’re creating jobs and striving to improve the overall quality of life for everyone in some way.”

And it’s where Stacey gets to enjoy a pick-up hockey game every now and then. It takes her back to some of her most memorable times of her life on the ice – playing for the women’s team in the Canada Winter Games and at Brown University before completing her eligibility and earning her degree in engineering at the University of Regina in Saskatchewan, Canada.

For Stacey, producing safe and affordable energy for the U.S. and improving the lives of people throughout North Dakota and beyond is the ultimate win. “At the end of the day, whether it’s out in the field or within the community, we’re one team.”

The Science Of Emissions Reduction

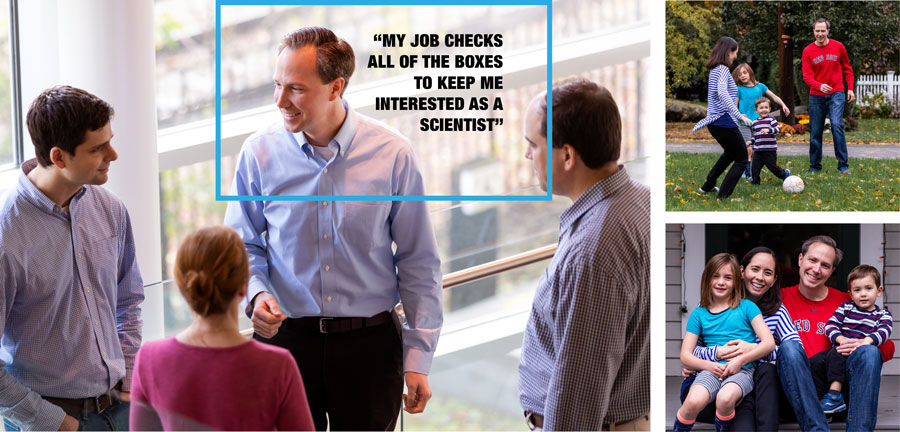

Schlumberger’s Drew Pomerantz Is Helping Industry Capture Methane.

It’s the summer of 2017, and Drew Pomerantz, a principal research scientist at Schlumberger, is walking around in the 100-degree heat of San Antonio, Texas, with what he describes as a “Ghostbusters” backpack. Along with his colleagues, he is testing the latest detection technologies to help address one of the natural gas and oil industry’s most important challenges – methane leaks.

“I got into science because I was always interested in understanding why and how stuff happens,” Drew says. “Things like, why this object is a certain color, or why some molecules have a chemical reaction when they collide, and others don’t react at all.” He realized early on that he needed a way to channel that intellectual curiosity in his work. He saw that opportunity at the intersection of energy and the environment. Drew is part of America’s Generation Energy: cognizant of energy’s role in building a cleaner world; highly motivated to advance climate solutions by developing and implementing cutting-edge technologies that increasingly capture more methane, the primary component of natural gas. Today he is a Ph.D. chemist at the Schlumberger-Doll research center in Boston, Massachusetts. One of his main jobs is to figure out how the industry can better detect and contain methane emissions during natural gas and oil production.

Methane emissions from natural gas exploration through distribution declined 16.2 percent from 1990 to 2016 even as natural gas production increased by more than 50 percent during the same time frame. Thanks to increased use of natural gas to fuel electricity generation, U.S. carbon dioxide emissions have fallen to 25-year lows.

Even so, Drew says the research he is doing can drive those numbers even lower in the near term. Indeed, lowering methane emissions is one of the many ways the industry is exploring zero- and low-carbon technologies.

“In order for natural gas to fulfill its societal role as a primary fuel source today, and a long-term partner to more intermittent renewable energy, we must reduce the environmental footprint caused by methane leaks,” he says.

It’s this truth that led Drew, his fellow scientists, and partners at the Environmental Defense Fund to the dry plains of Texas. His team had spent the previous two years exploring the hundreds of methane detection technologies being produced by entrepreneurs, academics and private corporations. They evaluated the business case and specifications for each and then invited the top 15 technologies out for a field test.

During that week, the Southwest Research Institute created a methane “scavenger hunt” for the scientists, allowing them to experience the full capabilities of each system. The main purpose of these technologies is to detect leaks during production. Recent scientific studies find that more than half of the industry’s methane leaks occur during production.

Today, well sites are often tested manually by specialized work crews that travel from site to site, often in remote locations. Yet, Drew points out that, for locations that are inspected regularly, about 90 percent of the time a crew will check a well pad and find that nothing needs to be addressed. A better idea is to use automated technologies to pinpoint issues so that crews go only where there’s a known problem. Drew believes the new technologies will be more efficient, saving time and other resources while reducing emissions even further.

“These sensors under development range from a couple of bucks to millions of dollars and everything in between,” he says. “However, exploring all of these technologies is important because there is no one-size-fits-all

Drew’s team is evaluating on-site sensors, sensors carried by airplanes and helicopters and the use of satellite technology to aid in detection. He is also partnering with operators, academics, environmentalists and entrepreneurs.

This collaboration is important for his research and the industry. Working together to solve these challenges is a key focus for groups like The Environmental Partnership, a collection of more than 50 natural gas and oil companies committed to further reducing methane emissions and improved overall environmental performance.

To participate in the Partnership, companies must be taking active steps to detect and reduce methane emissions. The organization also emphasizes learning between companies and promotes joint efforts to find environmental solutions.

If you spend five minutes with Drew, it’s easy to believe that the solutions for better detecting methane emissions are within the reach of knowledge and technology. And, it is inspiring to see a scientist who, nearly 20 years after he first began to explore this intersection of energy and the environment, continues to ask why, how and what’s next.

“My job checks all of the boxes to keep me interested as a scientist,” he says. “I am working on compelling research and placing papers in academic journals. At the same time, the research could have an impact within the energy industry and even on the planet.”

FOCUS ON Geoscience

WPX Energy geoscientist Danielle Martin comes to the natural gas and oil industry after being raised on the East Coast – where she never imagined working in oil country. Her work involves tracking oil wells from the conception and planning stages to drilling. “I think it’s exciting – to know that you’re providing energy to the world,” Danielle says. “Oil and gas is used in so many sectors.”

She helps reservoir engineers discover the geologic intervals to be targeted and then estimates the tops of formations in the subsurface to feed back to drilling engineers.

“I think it’s exciting – to know that you’re providing energy to the world.”

– Danielle Martin, WPX Energy

“It’s all about finding the best rock,” she says. “We think about what’s actually drillable now based on economics and spacing, as well as future wells that will be drilled in the same formation.”

Danielle’s appreciation for the natural gas and oil industry has grown as her career in industry has developed. It has brought home the roles of natural gas and oil throughout modern society. “It heats your home and raises the quality of life for people everywhere.”

Smarter, Cleaner Power Generation

Siemens’ Pratyush Nag Is Developing The Latest Turbine Technology To Amplify Natural Gas’ Role In Powering Americans’ Lives.

Every Sunday afternoon in Orlando, Florida, an all-girls middle school STEM team meets to work on designing and building a working car – from a mousetrap. At this age many students wouldn’t know where to start, but the award-winning trio made it to nationals last year and knows its stuff.

It helps having Pratyush Nag as coach – the father of one of the team members and the leader of natural gas turbine development at Siemens, where they know plenty about building a better mousetrap.

In the world of natural gas power generation technology, Pratyush brings the same excitement and commitment to meeting challenges and making the people around him better as he does while coaching his daughter’s STEM team.

Pratyush is part of America’s Generation Energy: thinking, creating and perfecting energy technology so that it better serves the people using it. At Siemens, it’s developing state-of-the-art electricity generation technologies fueled by natural gas. Pratyush’s team of world-class engineers collaborate 24/7 to build more efficient, economical and flexible power plants for the electricity that keeps our smartphones charged and our lights on while helping to reduce emissions by using clean natural gas as the generating fuel.

Access to reliable electricity marks a modern society, and this is underscored by America’s increasingly digitalized population. The cultural shift, which gained traction early in the 21st century, paralleled innovations in the natural gas industry – specifically, hydraulic fracturing and horizontal drilling. The marriage of these technologies made the fuel source more accessible and affordable for power generation. This is reflected in the marketplace, where natural gas increasingly is the generating fuel of choice by providers.

“Speaking from my own experience, the average residential electricity bill in the U.S. is relatively low,” Pratyush says. That’s of course because of significant American investment in fuel production, energy generation and distribution.

While affordability helped make natural gas the leading alternative to coal-fired generation, so did natural gas’ ability to reduce CO2 emissions. Thanks to its high-hydrogen and low-carbon content, natural gas can produce the same amount of energy as older, traditional generation sources, while releasing 50 to 60 percent less CO2, 80 percent less nitrogen oxides and particulate emissions, and virtually no sulfur dioxide and mercury emissions. This is one of the many reasons why Americans today are breathing cleaner air than they have in four decades.

Good is not good enough for Pratyush and his team. They wanted to create a natural gas turbine that could run more efficiently – producing more power from the same amount of fuel. So, they combined cutting-edge solutions with the best traditional technologies until they developed the H-Class gas turbine, breaking through the 60 percent efficiency mark – the energy conversion rate that’s a ratio of useful energy output from fuel input. This 60 percent efficiency barrier was a dream of engineers for several decades, during which combined cycle power plants have gradually inched from 45 percent toward 55 percent efficiency. “The air gets thinner, as we go toward the top,” he says. “It takes an incredible amount of technological advances to get to these last digits of efficiency improvements.”

“We called it our Roger Bannister moment,” he says, referring to the legendary British miler who was the first man to run the distance in less than 4 minutes in 1954.

“Engineers had tried for decades to meet that level of efficiency, but we got there first.”

From that proven H-class technology, Pratyush’s team recently created the smarter and even more powerful HL-class of gas turbines. Operating above 63 percent efficiency, this next-generation turbine is pushing the limits of generation performance. A single HL-class combined cycle power plant provides enough electricity to support the needs of approximately 3 million people. While these single-digit gains may seem small, their impact is massive. Running more efficiently, natural gas plants can generate more electricity at lower cost. This increases the likelihood that grid operators will dispatch that plant to meet a region’s electricity demands – boosting the use of natural gas while saving money for customers. This also helps the environment, because a two percentage point efficiency improvement with a Siemens HL-class combined cycle power plant means a reduction of CO2 emissions by 63,000 tons per year – the amount of carbon captured by nearly 75,000 acres of forests in a year.

While they can generate more power, the HL-class is smaller than its predecessors. Siemens manufactures huge sections of the power-plants, and then assembles them on site, as Pratyush points out, like giant Legos. But they leave room within the machine to add innovative technologies that will help the turbine operate at high-levels throughout its life.

“In the 30-year lifecycle, we plan for three to four upgrades, so the engines can be brought back to their original performance,” he says. “Maintaining this operating efficiency gives cost benefits to the customer while remaining environmentally friendly by keeping emissions low.”

Like much of the industry, Siemens uses digital solutions to help its turbines in power plants run more efficiently. While employees carefully set parameters and monitor the turbines, a machine-learning algorithm, a digital twin, is constantly analyzing thousands of data points based on real-life conditions. Using that information, it can tune the turbines to optimize their efficiency and further reduce emissions.

The role of natural gas in advancing climate goals also is seen with renewable energies such as wind and solar. Natural gas is the essential partner to their growth, with the HL-class turbines providing flexible baseload power when the renewables are offline – rapidly ramping up to generate 400 MW of power within five minutes and keep electricity flowing to the grid.

“This product is designed to meet the changes of the market dynamics while complimenting the world’s future energy mix.” he said.

That energy mix, today and tomorrow, will include natural gas and oil, providing safe, reliable and affordable energy while taking part in advancing climate goals. And while Pratyush will never stop pushing the limits to develop the next, greatest natural gas turbine, it’s the people he works with that make it all worthwhile.

“I am absolutely delighted by the people I work with,” he says. “The technology is cool, but my passion is the people. Over the last 17 years or so I’ve recruited and developed a lot of people into different roles in the company and watched them grow, and that is my greatest reward.”

Data-Driven Offshore Efficiency And Safety

Jennifer Osterhaus Of BP Is Using Technology To Responsibly Harness America’s Deep Water Energy.

The house is quiet at 5 a.m. as Jennifer Osterhaus sips her cup of coffee and reviews the family schedule for the day. Her eldest son has a baseball game across town, her daughter has soccer practice closer to home, and there’s the daunting task of keeping the 4-year-old entertained through it all.

You don’t have to be a chemical engineer to remain imperturbable in the face of many moving parts – but it doesn’t hurt any. “It’s all about the kids when I’m not at the office, and they keep me very, very busy,” she says. “At the office” for Jennifer is leading the operations support team for BP’s Thunder Horse platform in the Gulf of Mexico, the company’s largest offshore natural gas and oil production platform. She smiles when asked which is the bigger multi-tasking challenge: juggling her active family’s schedule or managing a modern platform in the Gulf.

Thanks to technology, running an offshore natural gas and oil platform has never been more manageable. Using world-class computerized data analytics, Jennifer and her team can monitor and evaluate the “health” of Thunder Horse from BP’s headquarters in Houston. Every day they analyze millions of data points in real time, which allows them to know that the platform is operating as it should, manage efficient production and improve safety – for BP employees and the environment – and even head off potential problems before they arise.

Jennifer is part of America’s Generation Energy: adept at using the latest technologies and digital solutions to safely deliver the natural gas and oil that drive the 21st-century economy and Americans’ modern way of life. Jennifer and her industry counterparts are working smarter and more efficiently than ever before while supporting workplace safety, infrastructural integrity and environmental protection.

“The technology allows us to filter out the inconsequential data and highlight the important issues, so our engineers can take action where needed.”

Thunder Horse represents U.S. offshore development that’s integral to America’s energy security. Located 150 miles southeast of New Orleans, the platform can reach energy reservoirs more than 6,000 feet deep and can produce up to 250,000 barrels of oil and 200 million cubic feet of natural gas per day – enough energy to power every home in Miami for a month. “There’s a lot going on in a relatively small and very remote area,” she says with an engineer’s professional calm. “Keeping all of it operating safely and efficiently is a challenge, but it’s also the most rewarding part of my job.” The 300 women and men who live and work on Thunder Horse are like Jennifer’s second family. Though the platform is hundreds of miles from Houston, her team is effectively right there, able to simultaneously monitor and lead platform operations and analyze constantly changing conditions through the Plant Operations Advisor (POA) solution, a tool created in partnership with BP and Baker Hughes, a GE company (BHGE). The POA system keeps tabs on about 1,200 pieces of equipment across BP’s four platforms in the Gulf of Mexico, including Thunder Horse, to ensure that everything operates within unique parameters. The technology processes more than 155 million data points per day and alerts Jennifer’s onshore team and the engineers on the platform if a component moves outside those parameters. Then, an employee on the platform, following personal and process safety protocols, takes action to gather onsite information.

“The technology allows us to filter out the inconsequential data and highlight the important issues, so our engineers can take action where needed,” she says.

That intel is combined with data about operations from that day, as well as trends over time, from POA. Accessing this information in the past could have taken weeks, but now it can be compiled in a matter of hours. If there’s an incident, the details help Jennifer and her colleagues perform a root-cause analysis, so BP can understand what happened, why it happened and what they need to do reduce the possibility it could happen again.

“The POA system will change the game,” she says. “We spend less time managing data and more time managing the overall health of the plant.”

Applying digital solutions to natural gas and oil operations across the country has created a vast collection of data. Access to it helps fine-tune operations, ultimately driving improvements in safety, efficiency and reliability. As the amount of information grows, next-generation technologies will use it to predict events months ahead of time and alert engineers before something has a chance to occur.

BP isn’t alone in achieving these objectives. All across the industry, operators are using similar and other technologies to help them meet and often exceed regulatory benchmarks.

Overall, industry’s success in these areas is based on its ability to be advancing new innovations for specific purposes, with operational flexibility.

Seeing Through Rocks

Data And Technology Help Devon Energy’s Alex Biholar Pinpoint America’s Energy Treasures.

Alex Biholar loves getting lost in the granite cliffs and natural springs found among Oklahoma’s thousands of acres of parks and wildlife refuges. Lugging his camera and tripod, he hikes for miles on any given weekend, capturing picturesque landscapes and closeups of granite-capped prominences that are more than 500 million years old.

The petroleum geophysicist for Devon Energy loves rocks and their history. He says that when you look at rock formations, you’re looking at time – time and also the energy riches that those formations create and hold: natural gas and oil. His work is a continuous quest for new discovery, capitalizing on technologies and analysis of massive amounts of data to reveal the earth’s otherwise hidden secrets.

“We’re optimizing production to levels once thought to be impossible,” Alex says. “As we continue to leverage new technologies that tell us even more about the earth’s subsurface, the opportunities within petroleum geophysics will continue to grow.”

Alex is a part of America’s Generation Energy: a modern-day treasure hunter whose discoveries help build American energy leadership, economic growth and the consumer benefits yielded by natural gas and oil and the countless products made from them.

Like other industry geoscientists, Alex uses “big data” analysis, high-tech computing and other technologies to develop a clear picture of the earth’s interior. Seismic surveys are vital in locating potential natural gas and oil reservoirs. Though seismic research has been around for decades, innovations in the technology have taken survey results from a 2-D “picture,” merely identifying the existence of underground deposits, to today’s detailed, 3-D seismic images that greatly reduce the possibility of drilling dry holes.

During the survey process, when sound waves sent into the ground hit rock, they bounce back to the surface and are recorded by multiple nearby geophones. The recordings are uploaded onto super computers and integrated with other acquired data. Combined, these create 3-D images that illustrate the underground layers, thousands of feet below the earth’s surface.

From his office in Oklahoma City, Alex reviews the collected field data to understand the depths and orientations of rock formations and determine the sweet spot for exploration and production. These advancements provide companies with greater certainty in exploration, help to maximize production, reduce costs to consumers and minimize the industry’s footprint.

“We analyze and interpret immense amounts of data, terabytes each day, to build our own treasure maps and essentially see through the rocks,” Alex says. “And thanks to the integration of advanced technologies, we do this with amazing precision.”

Everyone has seen photographs of “gushers” that signified striking oil back in the industry’s early days. Today, science and technology point to natural gas and oil miles underground. The exhilaration is the same once the reservoir is confirmed, he says.

“These projects become your baby. You work tirelessly to identify the best locations to drill. And as they produce and even break records in production as we recently did in southeastern New Mexico, the feeling is indescribable. It’s beyond rewarding to know that we’re a part of the work that’s powering the world.”

While in-depth analysis from experts is critical to selecting the right drilling location, today’s highly digitized industry is collecting and synthesizing natural gas and oil data on an unprecedented level. Progress in data analytics is accelerating. And the use of seismic techniques doesn’t stop at the prospecting stage. Today, 4-D seismic data, which is made by overlaying the 3-D readings of a single location over time, shows the patterns of movement for subsurface natural gas and oil. These views enable companies to plan future operations.

Alex notes that while high-tech supercomputing has significantly enhanced all aspects of the industry, the physical exploration of the natural world is just as important. Hence, the satisfaction he gets from those weekend hikes.

“Modeling is an approximation of reality. Some of the best geoscientists are those who’ve seen the most rocks, those who constantly yearn for a deeper and wider understanding of the subsurface.”

“To understand rocks and depositional systems and what they’re capable of, you have to experience them in their natural habitat. It’s pattern recognition. That’s how you maximize predictive analytics.”

Natural gas and oil companies are ranked among the largest employers of geophysicists. For Alex and his colleagues across the industry, the work is about safely uncovering resources for today and tomorrow, ensuring that the hunt for natural gas and oil is precise, production is optimized and the environmental impact of operations is minimized.

“That’s treasure hunting at its best.”

FOCUS ON WELL PRECISION

Halliburton’s Shobhana Mani is the company’s director for technology, drill bits and services, and was part of the company rollout of Cerebro in-bit sensor technology that sends data directly from an operating drill bit and analyzes it to optimize performance and efficiency.

The technology captures downhole vibration and motion data – including lateral and axial vibration, torsion resistance and other factors – that can affect drilling speed and efficiency. The information helps operators pinpoint where bit damage occurred and when optimal performance is not achieved due to inconsistent design or operating parameters.

“For the first time we have a look at what’s happening downhole,” Shobhana says. “It is extremely exciting to see what the potential of that data is, and it really helps us imagine the drill bit in ways that we never did before.”

“To me, as a technology person, it’s extremely exciting, and it opens up a world of possibilities.”

– Shobhana Mani, Halliburton

On a recent set of runs, Cerebro acquired information that allowed the operator to utilize a more assertive cutting structure to increase drilling efficiency and reduce well time. This data also showed that higher drilling speeds could be used in softer sections of the well without vibration limitations. “To me, as a technology person, it’s extremely exciting,” she says, “and it opens up a world of possibilities.”

Always On Guard

Through Advanced Cybersecurity, Chevron’s Marisa Ruffolo Protects Vital Energy Infrastructure.

It’s before dawn as Marisa Ruffolo flows from one yoga pose to the next before heading off to work. Her mind is calm and singularly focused. The class is a kind of controlled endurance trial. It’s a fitting workout, especially the mental preparation, for the kinds of challenges she faces every day as a cybersecurity enterprise architect at Chevron.

Marisa is part of America’s Generation Energy: deploying technologies to support best-in-class cybersecurity standards, protocols and collaborations that safeguard industry and help maintain American energy leadership.

As the job title above suggests, Marisa is a designer and builder. Not of physical structures, but of solutions – measures to defeat cyberattacks targeting industry operations and intellectual property, from corporate offices to well pads to pipelines – which if successful could impact U.S. energy and national security. The threat never rests; neither do Marisa and her industry counterparts. “At some point you come to terms with the fact that the adversaries are out there, and that there will always be those who are looking to do you harm,” she says.

The digital solutions of the 21st century have increased the reliability, efficiency and safety of natural gas and oil operations to unprecedented levels. Advanced security means Americans can have reliable access to cleaner and more affordable energy options that power their modern lives.

With these benefits also come a growing number of cyber-based attacks on the operational technologies that monitor and control rigs, wells, pipelines and refineries.

Countering the threat are today’s industry cybersecurity professionals, who represent a diverse and well-trained cadre of specialists. Collectively, they protect the industrial control systems – the digital brains of physical assets – as well as the information technology, which stores and protects intellectual property and other corporate data, preventing energy disruptions that could harm national security and the public. All but gone are the days when hackers living in their parents’ basement dreamed up nuisance attacks for kicks.

“Sharing helps us better understand whether a threat is just focused on one company or is an industry-wide attack.”

According to Marisa, the modern hacker – or “adversary,” as they are known in cybersecurity circles – is as highly skilled, motivated and proficient as the experts assigned to protect against their attacks.

“Today’s hackers are educated engineers and computer science professionals who have been hired by nation states or cybercriminal organizations to develop attacks against companies and governments,” Marisa says.

Recognizing today’s realities, natural gas and oil companies recruit talented professionals to stay a step ahead in a cyber chess match that’s anything but a game. Marisa is one of the leaders in her field. An electrical engineer by training with a doctorate from Northwestern University, she spent seven years at a national laboratory, exploring the role of cybersecurity in national defense applications.

These days, well-educated cyber professionals have the attention of industry’s C-suite executives, helping natural gas and oil transition to a new, state-of-the-art level of preparedness. A number of corporate boards and executives are actively engaged with their growing cybersecurity departments as they execute defense-in-depth approaches to cyber protection. Marisa says that executives focus on cybersecurity because they see it as enterprise-wide risk management, placing it among the highest levels of corporate priorities.

The focus on security is prevalent even at the most basic operational level. Safety briefings before worker shifts at refineries, pipelines and well sites long have been an industry practice. Marisa notes that Chevron now also focuses specifically on cybersecurity concerns, such as phishing attacks and critical security updates, during these safety briefings.

In addition to this focus, she says that information sharing across the industry and with government agencies makes a real difference in identifying and addressing attacks. Threat information and indicators of potential security breaches are shared by the U.S. intelligence community with cybersecurity experts from natural gas and oil companies as well as industry collaborations like the Oil and Natural Gas Information Sharing and Analysis Center (ONG-ISAC) on an ongoing basis. Threat countermeasures are continually incorporated into company cybersecurity programs.

“This sharing helps us better understand whether a threat is just focused on one company or is an industry-wide attack,” she says. “When we have a better understanding of the adversary’s target, we can more efficiently respond.”

That response is built on international standards and proven guidelines including a Cybersecurity Framework established by the National Institute of Standards and Technology (NIST) with five core focus areas: identify, protect, detect, respond and recover. This same framework is used across U.S. industries from banking to manufacturing. A disciplined approach to protection is necessary because the fight is never over.

“The energy industry is so important to our economy, so it makes sense that adversaries would want to disrupt it through cyberattacks,” Marisa says.

Her day ends much as it began on the yoga mat – with unwavering focus. Fortunately, the natural gas and oil industry – and a country that counts on secure, reliable energy – has cyber defenders like Marisa Ruffolo.

Optimizing Pipeline Performance

Alyeska Pipeline’s Klint VanWingerden And Cutting-Edge Technologies Keep The Trans Alaska Flowing.

In a garage near Anchorage, Alaska, Alyeska’s Klinton “Klint” VanWingerden is preparing for the Iron Dog – the world’s longest, toughest high-speed snowmobile race, covering 2,000 miles of some of the most remote and rugged terrain of America’s Last Frontier.

Klint and his partner form the “Sons of Thunder” racing team, and they have a pair of brand-new snowmachines (as Alaskans call them) for the next Iron Dog: one they beat up during rigorous testing before the race, and another that the “Sons of Thunder” will tweak and fine-tune for the real competition, using what they learned during pre-race trials.

Cutting-edge technology, preparation and a solutions-oriented approach win snowmachine races. All three also apply to running a modern energy pipeline like the Trans Alaska Pipeline System (TAPS), which Klint and others manage from Alyeska’s Operations Control Center in Anchorage.

Klint is part of America’s Generation Energy: committed to using the most advanced technologies, engineering and pipeline management systems to ensure safe delivery of crude oil – in the case of TAPS, oil from one of the United States’ largest reserves.

In service since 1977, TAPS is key to U.S. oil supplies of today and tomorrow, thanks to additional resources that may be tapped in the Beaufort and Chukchi seas off Alaska’s northern coast and on the coastal plain of the Arctic National Wildlife Refuge.

At the control center, Klint and his team have remote visibility and control of TAPS, stretching 800 miles from Prudhoe Bay on Alaska’s North Slope down “south” to Valdez, the northernmost ice-free port in North America.

Alyeska’s expert controllers constantly monitor flow through the pipeline in the state-of-the-art control center, enabling quick adjustments to any operational fluctuations. This helps ensure safe and efficient operations of the pipeline, its multiple pump stations, and the Valdez Marine Terminal, where crude oil is measured, stored and loaded onto tankers for transport to the Lower 48.

As one of the world’s largest pipeline systems, TAPS is the lifeblood of Alaska’s economy. According to reports, the natural gas and oil industry supports nearly one-third of all jobs in Alaska. In 2017, natural gas and oil revenues represented 65 percent of the state’s unrestricted revenue.

For Alaskans, the natural gas and oil industry is as much a part of the state’s rich culture and way of life as its diverse terrain, mountains and abundant wildlife.

“The same fuel that powers my snowmachine, dirt bike and even my family’s love of hunting and the great outdoors allows us to enjoy our great state in so many other ways,” says Klint.

This is Klint’s life’s work, as it was for his father, Doug, and is for his brother, Kristopher. Doug worked for BP on the North Slope for more than 30 years, doing all kinds of work across the field and eventually advancing through the company to support the operations, safety and integrity of the system before he retired. Kris is a controls and automation engineer for BP, supporting its pipeline operations on the Slope.

This same industry funded Klint’s way through college. An Alaska Native, he received scholarship aid from the natural gas and oil industry, which helped him earn his bachelor’s degree from the University of Alaska-Anchorage’s science and engineering program. His education has helped him stay nimble professionally as the industry grows and transitions, and as more operational segments are leveraging cutting-edge technologies.

“As technology continues to evolve so rapidly, the Trans Alaska Pipeline is equipped to transform with it – to improve operations as well as to bring more oil to market from untapped resources,” he says. “That’s important to the future of Alaska, and we’re proud of the innovation and advancements that are bringing more diverse work opportunities to Alaskans.”

Klint talks of artificial intelligence and other technologies that continue to be integrated into the natural gas and oil business and how advances are letting industry use machines for the action- and reaction-oriented tasks that previously were performed by workers out in the harsh Alaskan terrain. Remote diagnostics, in particular, allows highly skilled experts to remotely guide local technicians to specific points along TAPS to maintain equipment – keeping more workers in safer environments and increasing the pipeline’s effectiveness at the same time. Alyeska and other industry partners won one of the federal government’s Unmanned Aircraft System Integration Pilot Program spots, so they’ll be testing drones for various types of operations along the pipeline.

“These advancements allow the industry to be more proactive and enable our workforce to perform higher-level thinking – the work that is more complicated to automate.”

Klint’s enthusiasm for the industry and where it’s headed is largely driven by the opportunities he believes lie ahead for future generations.

Connecting Communities And Natural Gas & Oil

Jennifer Smith Of Enbridge Listens, Engages And Builds Relationships – One Handshake At A Time.

Jennifer Smith tells a story from a few years ago when she represented Enbridge at a township council meeting as the pipeline company was preparing to add pump stations to one of its lines. Folks had frank questions, yet after a conversation that lasted a couple of hours, there was common ground. The effort earned her a rare honor: an invitation.

“This council member asked me to stay for cake,” she recalls – specially baked by a member’s wife for an invitation-only refreshment session. By the end of the evening she felt like she was part of the family, “adopted” by the community because she was invested in it – engaged in constructive dialogue and mutual understanding. It’s her job and her gift: the ability to listen and engage transparently.

Jennifer is part of America’s Generation Energy: an advocate for U.S. natural gas and oil, their infrastructure and the way they power and support modern society.

As a community engagement professional for Enbridge, Jennifer’s role is connecting Americans with the benefits of safe and responsible natural gas and oil development, pipelines and other energy infrastructure – while listening to and addressing their questions with the goal of forging lasting partnerships.

“People don’t realize how much we rely on these products,” she says. “We enjoy a nice quality of life here in the U.S., and the natural gas and oil industry is an important reason why. When I talk to people about the benefits of natural gas and oil, I always love to see that lightbulb turn on when they realize the role our industry plays in supporting that quality of life.”

Foremost is the reality that energy projects, such as an Enbridge pipeline, support economic growth and value in hosting communities – from good jobs with family-sustaining salaries to support for other businesses, including grocery stores, restaurants, hotels and more. The energy industry adds tax revenues that support local school systems, roads and emergency services, and its employees help strengthen the overall quality of life in the communities where they live by joining, volunteering and participating in local activities.

Based in Duluth, Minnesota, just across Lake Superior from Enbridge’s Superior, Wisconsin, liquids terminal – through which more than 2.5 million barrels of crude oil pass daily – Jennifer’s real office is wherever there are people to engage in conversation about the benefits of pipelines. Out there, she relies on what she calls “eye-to-eye” time and “a listening ear” to be effective.

“Pipelines are a linear asset, and you have to travel to reach all the communities along our systems,” she says. “I love getting out there and taking that time to form relationships built on trust and respect. We meet with anyone willing to talk and transparently answer their questions, bringing in our experts whenever we can to ensure everyone is knowledgeable about our work.”

Sometimes the work can be challenging. She remembers sitting next to a gentleman on a flight who clearly was skeptical about the industry. The gentleman expressed his concerns about the industry, and Jennifer listened. By the end of the flight, they came to better understand each other – so much so that he invited her to visit his dress shop the next time she was in town.

A big part of Jennifer’s approach is interacting with people as a fellow member of the community. A sign over the fireplace in her home reads, simply, “Family.” She, her husband and their two teenagers are enmeshed in life in Minnesota. Chicago-area transplants, their daughter is a fast-pitch softball player and their son is a rising hockey player. (Hockey is another opportunity: She tries to help her son and his friends understand that the hockey pads, jerseys and helmets they wear on the ice all are made from or with the help of petroleum.)

Enbridge encourages engagement in all forms from its employees, she says, to develop a sense of giving back to the places where they live and work.

“Who is a more credible spokesperson for this industry than someone who really lives here and is invested in what’s best for this community?” she asks. “I am proud to be a part of these communities, and I am proud of Enbridge because I know how important our work is for this country, and I see the passion of the people operating our pipelines.”

Whenever she feels fatigued by the cause, Jennifer doesn’t hunker down in her office. She looks again to the communities she serves. “Whenever I start to lose some steam, I go out and do some outreach because it is amazing. People all have their own stories and perspective. When we share our views openly with each other, we find common ground and can work together.”

Living The Safety Culture

Shell’s ‘Mac’ McLendon Brings His Own Energy To Protecting Offshore Workers And The Environment.

It’s the first cool day New Orleans has seen all year, and Lautrice “Mac” McLendon isn’t letting it go to waste. As part of Shell’s effort to give back to the community, McLendon and 20 of his co-workers are making upgrades to a Mid-City home damaged by hurricanes.

Before he dabs sealant on a new backyard fence, Mac replaces his everyday bifocals with plastic protective glasses. Safety first. Whether he is helping revive still-recovering neighborhoods of the Crescent City or working toward a zero-incident day with one of Shell’s many Gulf of Mexico assets, safety always comes first.

Mac is part of America’s Generation Energy: focused on safe offshore operations for all of Shell’s employees and contractors, and its drilling and production platforms – protecting both them and the marine environment.

Mac and his industry counterparts are dedicated to safety processes and collaborations that help improve offshore energy development – itself strategically vital to U.S. energy security.

The natural gas and oil industry has long devoted significant resources to continuous improvement of operational safety in remote and challenging offshore environments. The 2010 Macondo incident led to the creation and strengthening of more than 100 industry exploration and production standards,42 the establishment of the Center for Offshore Safety and a new generation of collaboration by companies, regulators and experts to broaden industry’s offshore safety culture. Many professionals like Mac are charged with making offshore safety happen in real time, and no one is more excited about it.

“Every person is not only entitled to shut down the facility if they see something going wrong, they are expected to do so.”

This commitment to safety begins before wells are constructed. Shell and other offshore operators take virtual pictures of the rock beneath the sea floor using 3D seismic imaging. This helps them better understand the geological makeup and potential energy opportunities in the area, allowing for more precise exploration and safer well designs. By reducing the number of test wells drilled, there’s also less impact on the surrounding environment. Shell also runs the Robert Training and Conference Center near New Orleans to train employees and contractors before sending them offshore, using virtual reality, control-room trainings, lifeboat simulations and more. It’s evidence of industry’s offshore safety commitment that other companies are welcome to send their workers to the RTC for training. Once a platform is built – basically, a self-sufficient city on the water – it’s populated with scores of skilled workers. They, like Mac, leave families for weeks at a time to produce the energy that powers and supports the U.S. economy and Americans’ lives. Mac’s offshore story actually started as an electronics technician in 1998, working his way up to his present position as Shell’s general manager for safety and environment for all of the company’s Gulf producing assets. When he worked away from his wife and three kids, Mac saw his offshore co-workers as his second family. Unlike a traditional family structure, where parents have the last say, everyone has a say in the interest of safety. On a platform miles from shore, not only is everyone empowered to speak up, they’re expected to alert superiors if they see something. “When we say, ‘Goal Zero,’ we want every person, every day on every task to do the right thing, even at the expense of production,” he says. “Every person is not only entitled to shut down the facility if they see something going wrong, they are expected to do so.”

Though he spent many years in the Gulf of Mexico, Mac is now based in New Orleans – home to one of Shell’s Real-Time Operations Centers. Running 24/7, the center monitors every aspect of specific platforms and alerts engineers offshore if variables move out of an ideal operating range. For example, they can detect potential leaks by carefully monitoring pressure and temperature changes. They also use vast amounts of data collected to predict and prevent potential events. Across the industry, similar measures are deployed to meet or exceed regulatory requirements. Industry’s overall success is linked to the ability to continuously advance new technologies for specific purposes with operational flexibility.

On the platform itself, many engineers and technicians are using tablets to receive real-time information, constantly checking operations against baseline safety management system protocols. Safety is augmented in a highly digitalized era. Yet, as Mac notes, the offshore’s digital transition is carefully managed. Even the most innovative technologies are thoroughly vetted, tested and piloted before being implemented on an offshore platform. These support 24/7 vigilance by skilled professionals, regulators and other third-party inspections.

“We’re of the mindset,” says Mac, “that we must perfect every technology to the point that we’re not introducing another hazard into a challenging environment.”

And though this culture of safety is foundational across Shell’s worldwide operations, Mac and his colleagues are always looking for ways to strengthen it. So, they work with academics, technical experts and fellow natural gas and oil companies to regularly share best practices and apply lessons learned. This is critically important in the Gulf of Mexico, which Shell and other operators have made one of the United States’ most productive offshore reserves.

“My biggest reward and also my greatest challenge in this job is collaborating with my onshore and offshore colleagues effectively because, as I always say, one Gulf of Mexico is simply safer.”

Mac’s efforts also support something greater for Louisiana and the Gulf Coast. In the Gulf of Mexico, Shell currently operates many kinds of platforms and systems. Shell has been an offshore pioneer in the Gulf for more than six decades and has achieved technological milestones in the design, construction and operation of offshore production, to which safety is fundamental.

Properly implementing and educating people on these practices and standards is a passion of Mac’s. So he does whatever it takes – from managing discussions between onshore and offshore engineers every day to collaborating with industry leaders across the Gulf. The results are very good. In 2016 the U.S. Interior Department’s Bureau of Safety and Environmental Enforcement reported a 35.6 percent drop in offshore incidents compared to 10 years earlier.

For Mac, it’s more than a statistical trend line. Safety is personal. “I’ve always had a passion for people and educating them,” he says, “so they can go home to their families.”

FOCUS ON SAFETY

Corena LeDonne has been with Chevron for 28 years and a firefighter with the company’s Richmond, California, refinery for the past 16. Chevron is the only refinery with a full-time fire crew, additionally supported by a volunteer fire brigade. This means that the Chevron crew responds to incidents not only at Chevron’s refinery but at any refinery in the region.

Refinery firefighters are responsible to Chevron, to the Richmond community and to fellow Bay Area firefighters. No day is typical. “Every day is never the same,” she says, “you never know what you’re going to get.” Her department answers medical calls and manages work permits whenever there’s a job that involves any type of spark, such as welding.

Corena’s passion for boating led her to jump at an opportunity to introduce a fire boat to her department and train a crew to use it. The fireboat is used mostly for security rounds for the tankers. But it’s also outfitted to respond to on-water incidents, and having its own boat makes her department more nimble in response in these situations. “I’m very happy,” she says. “I never get bored.”

“I’m a lucky girl. This is a great job.”

– Corena LeDonne, Chevron

Extending U.S. Energy Leadership

Cheniere Energy’s Tyler Pedersen—On The Frontier Of Exporting U.S. Natural Gas.

Bell City, Louisiana, is little more than a post office, a school, a stop sign and St. John Vianney Church – all collected around an elbow jog in state highway 14, about 25 miles southeast of Lake Charles and 30 minutes north of the Gulf of Mexico.

It’s rural, which is the way Cheniere Energy’s Tyler Pedersen likes it. It’s where he learned skills that led to a rodeo scholarship at McNeese State University and where he’s taught his children how to put in an honest day’s work on the family farm – room to rope and ride and enjoy a unique culture that’s a throwback to America’s pioneering era. Tyler and Cheniere are pioneers as well.

America’s natural gas abundance, coupled with the construction of new infrastructure to export liquefied natural gas (LNG), has opened new frontiers for the United States as a global energy leader, helping friends and allies, growing trade and supporting energy jobs here at home. Tyler, a supervisor of pipeline and midstream reliability services for Cheniere, senses the next-generation moment afforded by plentiful domestic energy.

“Being at the forefront of a rapidly expanding industry happens once in a lifetime, if you’re lucky,” he says. “At Cheniere, we’re setting the pace and cutting the trail for the rest of the U.S. when it comes to exporting LNG. And being part of their team is incredibly rewarding.”