Energy Is Powering Innovation

Natural gas and oil are integral to innovations that safely and efficiently supply the daily energy Americans need, as well as the modern products that make lives safer, healthier and more convenient. Natural gas and oil also boost innovation in other fields that support growth, prosperity, discovery and human advancement.

- Pinpointing Energy Reserves

- Precise And Efficient Production

- 24/7 Infrastructure Monitoring

- Expanding Natural Gas Availability

Innovation Is Revolutionizing The Oilfield

Eric Holderby

Eric Holderby

District Technology Manager, Halliburton – Oklahoma

“We collect data on everything and are constantly using it to learn more about our operations.”

The natural gas and oil industry will long be associated with the hard work of oilfield workers – iconic in their hard hats, coveralls, heavy-duty leather gloves and work boots as they maneuver lengths of steel pipe and perform other tasks on a drilling platform or at a well site.

While those men and women are still there, performing essential on-site functions, today’s industry has a high-tech dimension as well, with innovative technologies and computer-assisted data management and analysis playing leading roles in the ongoing quest to safely and responsibly develop the energy the United States needs.

What might surprise the 55 percent of American consumers recently surveyed, who immediately think of roughnecks when they think about industry, is that many industry jobs actually take place inside office buildings, laboratories and research facilities. And many of the men and women wearing hard hats and coveralls at a well site today are highly educated engineers and scientists.

Halliburton is among the many companies pioneering high-tech approaches to energy development. “The historic belief that our industry is slow to adopt technology simply doesn’t hold true,” says Stephen Ingram, the company’s vice president of technology solutions and innovation. “In the last 10 years the industry has been transformed through advances across every aspect of oil and gas development, from advances in the drill rig and in directional drilling technology, to innovations that improve logistics and infrastructure.”

Inside a hydraulic fracturing site control room is a great place to see the industry’s high-tech nature in action.

Halliburton District Technology Manager Eric Holderby, 31, leads a group of about 90 engineers, chemists and scientists, many of whom work alongside him on the front lines.

“Technology supports everything we do,” says Eric. “There are a lot of things going on at the well site, and we’re monitoring all of it. We can control and make adjustments from right inside these rooms – it’s pretty astonishing.”

Eric describes his team’s work as a continuous learning effort. “Our work has become incredibly data-driven. We collect data on everything and are constantly using it to learn more about our operations. Our industry has a huge impact on everyone’s daily lives, so optimizing deliverability is critical. With the data we collect, we’ve made huge gains in knowledge. That translates to more affordable energy, more efficiently delivered.”

These days, Eric is most excited about the company’s new Remote Operations Command Center (ROCC) in El Reno, Oklahoma, the largest Halliburton ROCC in North America. “We can see and make changes to jobs that are happening in locations all over the country from this flagship hub,” he says. “Five years ago, I wouldn’t even have thought this was possible, but this is where we are today.”

As Ingram explains, “The industry is transitioning in real-time. We’re moving away from old ways of doing business to how we will be doing business in the future.”

Fortunately, the labor force is changing, too. “A lot of the people reporting to me are just out of school,” Eric says. “And the more we advance technologies, the more we can attract young, talented people who want to be part of innovation. This is not the oilfield days of old.”

Innovating To Meet Challenges Today And Tomorrow

The future belongs to the innovators – people and industry sectors that can create and deploy advanced technologies, systems and processes to meet the challenges of tomorrow.

The men and women of the natural gas and oil industry are innovators, with a history of taking unique and technology-driven approaches to problem solving in the energy space. We innovate to bring energy to Americans safely and efficiently, recognizing that energy is essential to Americans’ security and the foundation of individual opportunity and well-being. We also support the innovation of others, supplying fuels, products and the chemical building blocks needed to foster growth, prosperity, discovery and human development.

Innovation is at the heart of what we do: finding and producing natural gas and oil. Innovation spurs safe operations, and it allows us to increasingly minimize our environmental footprint.

From Edwin Drake’s first oil well in Pennsylvania in 1859 to today’s advanced, computer-assisted technologies that leverage data analysis and science for precision in exploration and production, the natural gas and oil industry has come far by meeting challenges through innovation.

Innovation is apparent in virtually every step of natural gas and oil development.

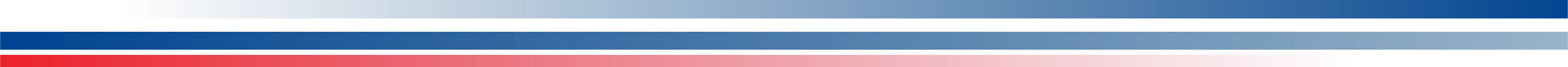

We innovate to better locate and develop natural gas and oil reserves thousands of feet below the earth’s surface and tens of thousands of feet below the ocean floor. With cutting-edge imaging technologies, knowledge of petrophysics and the use of algorithmic data analysis, operators can understand where to explore in a given geologic profile. And, thanks to the technical ability to drill horizontally for thousands of feet in any direction from a single vertical shaft, our surface footprint is smaller, and there’s greater production and cost efficiency with each well.

There’s innovation once the well is developed, with portable control rooms that resemble those at NASA, managing hydraulic fracturing to safely release natural gas and oil molecules from tightrock formations – uneconomic just a decade or so ago. More energy is being developed from each natural gas and oil reserve through advancements in hydraulic fracturing, sand volume, spacing, lateral placements and enhanced recovery technologies. With fiber optics and other technologies, operators can monitor and manage downhole activity, including the process of completing a drilled well to start the flow of natural gas and oil.

America’s energy renaissance, which has made our country the world’s leading natural gas and oil producer, is driven by technology and innovation.

Innovation also is embedded in safety – for workers and the surrounding environment. Breakthrough, “smart” technologies are used to identify potential problems before an incident occurs and protect pipelines from threats such as corrosion. Innovative processes allow pipelines to cross well beneath river bottoms without disturbing the river or surrounding environment. Technology is helping reduce the emission of greenhouse gases, such as methane, through state-of-the-art leak detection and advanced equipment designs.

Natural gas and oil also fuel innovation in other fields. These include science, medicine, health care, communications technology, transportation and the arts, and they serve as the chemical building blocks for countless products. Natural gas and oil play these essential roles because they’re abundant, reliable, versatile and packed with energy content. Other energy sources don’t have the adaptability and usefulness of natural gas and oil when it comes to supporting innovation – from routine items like moisture-wicking clothing to high-tech, 14-layer space suits astronauts may one day wear on Mars. Natural gas and oil provide manufacturers with the chemical feedstocks to support drone technology, development of exoskeleton suits, robots and more.

Our companies are even investing in enhancing other energy sources, such as solar, wind and advanced biofuels, including those made from algae and cellulosic sugars. All of these are in addition to thousands of consumer products Americans use every single day.

Past and current natural gas and oil innovation set the foundation and shape the mindset for future innovation – for technologies on the drawing board as well as those that are just a glimmer in the mind of an industry scientist, geologist or engineer. We innovate and develop technologies for the future because it’s our history and mindset.

“[I]n a free society solutions are eventually found. And in the long run, the new developments leave us better off than if the problems had not arisen.” – Academic Julian Simon

The following cards describe just some of the innovations industry uses to make energy exploration more precise and production more efficient, which enhance environmental progress.

Innovation From Start To Finish

Across the industry, innovation is leading the way.

The technologies that follow are used by companies across the industry for safety, better and more efficient production, energy management and delivery, refining, and power generation and storage. Efficiency and safety protect workers and the environment, and help manage production costs.

Continuous, simultaneous management of multiple drilling rigs from centralized support centers helps ensure safe and efficient operations in real time.

Individual sites and service companies are using virtual reality tools to train plant crew members. This gives new employees, or those in need of a quick indoor refresher course, the opportunity to walk a refinery and learn about its processes without ever getting their boots dirty.

Data analytics increasingly guide industry operations, from exploration and development to transportation to refining. Operators can crunch data to determine the safest, most productive ways to develop, transport and process natural gas and oil. Companies analyze data from their operations to streamline processes and make the best tactical decisions possible.

IIoT-enabled facilities have transformed for the future. For example, refiners can monitor data closer to its source, coordinating maintenance and connecting workers. Companies carefully manage access to IIoT control systems and infrastructure, working with security firms to protect data integrity and process controls.

Drones and robots can make it easier to access difficult or remote operational areas to analyze equipment integrity, collect data and provide situational awareness with less risk to personnel. At refineries, for example, drones may be used to analyze gases and to check the integrity of the stack itself, reducing the need for interruptions to operations.

Listening devices at the surface and down the well help locate the origin of fractures in reservoir rock, to help plot the location of petroleum reserves, increasing production efficiency.

The most effective drilling locations may be predicted using physics and a technology known as machine learning. An algorithm also can help guide drilling, while multivariate statistical models can predict sweet spots in geologic formations.

Temporary fiber optic cables can be put inside a well to collect a variety of data and allow operators to observe the well’s performance in real time. Permanent fiber optics help measure production flow and the effectiveness of well completions work.

Sound waves and processing technologies, inversion modeling and imaging algorithms help map subsurface conditions – onshore and offshore – to provide greater certainty in exploration and production and minimize the surface footprint.

A number of strategies have the same goal – using less fresh water for hydraulic fracturing operations. Some companies use brackish water or wastewater, while others have invested in filtration and other processes to reuse water that is produced during well completion. These processes save water and reduce the number of trucks needed to haul in water for operations.

Through the use of sound waves, engineers can understand the physics of rocks and predict how much natural gas and/or oil may be produced.

From a single vertical well, multiple horizontal wells can be developed, limiting the surface footprint. These laterals allow more efficient natural gas or oil recovery in energy-bearing strata, or the use of enhanced recovery methods, such as steam, to maximize production, especially in heavy oil plays.

Industry uses specially advanced equipment and state-of-the-art processes to design and construct pipelines with the highest grade of steel, with strengths typically ranging from 70,000 to 80,000 pounds per square inch (psi). Armored tanks and personnel carriers use grades of steel in the range of 36,000 to 50,000 psi.

Diagnostic tools traveling inside pipelines scan the walls with technologies similar to an ultrasound or MRI to locate even microscopic cracks. They’re part of the reason operators are able to prevent incidents before they occur.

From infrared cameras to fiber optic cables installed alongside a pipeline, operators are employing new technologies and techniques allowing for 24/7 monitoring, ensuring if a leak does occur it can be quickly identified and potential impacts mitigated.

Operators often use steerable, trenchless tunneling to lay pipeline under a river or road without affecting the surface. Directional tunneling reduces the surface construction footprint and decreases the possibility of erosion.

Focused on preventative maintenance, operators are using robotic crawlers to scan and detect features in facility pipelines that are smaller diameter and have multiple bends.

To meet new global standards, ships today use low-sulfur fuel types, including diesel, liquefied natural gas, methanol, ethanol and biofuels, among others. As the fuel industry expands, commercial economics, infrastructure and availability are the key factors that will continue to drive innovations in global shipping.

Technologies are being developed to capture carbon dioxide from power plants and factories, helping to reduce CO2 emissions and potentially making natural gas-fueled electricity generation even cleaner.

Working with rail tank car builders and railroads, industry has sought improved designs and effective standards – including thicker steel, enhanced thermal protection, extra shielding at the car’s ends and improved pressure release valves. These make shipping crude by rail, already with a 99.999 percent safety record, even safer.

Refined products must be consistent in availability, cost and quality, yet raw materials and market conditions constantly change. Refiners continuously analyze each process unit – from distillation columns to hydrocrackers to naphtha processing units. Specially designed online processing control technologies help maintain safe and steady operations, optimizing production.

Natural gas to generate power, combined heat and power, microturbines and natural gas direct carbon fuel cells are examples of innovation bringing the benefits of natural gas to homes and businesses.

Companies are investing in technologies that help improve air quality by reducing refinery energy consumption. A good example is on-site cogeneration plants that recover a refinery’s waste heat from one process and use that to power another process.

Vessels that can store, transport and return liquefied natural gas to a gaseous state right onboard help make natural gas available to more markets around the world.

Fuel cells provide critical energy backup for many large facilities, and they can provide primary energy for remote locations. Fuel cell technology generates electricity from hydrogen while emitting nothing but water.

Technology And Innovation Foster Safety And Integrity

Leslie Fangue

Leslie Fangue

Facility Integrity Manager, Plains All American – Texas

“In reality, pipelines are one of the safest ways to transport crude oil and natural gas, especially across great distances.”

The U.S. pipeline industry safely and reliably operates hundreds of thousands of miles of delivery infrastructure across the country – bringing petroleum and petroleum products from production areas to refineries to consumers and manufacturers – thanks to a specially trained workforce that’s aided by continually advancing technology and innovation. It’s an equation that has produced a 99.999 percent transportation safety record.

Plains All American owns and operates 20,000 miles of North American pipelines, transporting crude oil, natural gas, natural gas liquids and the finished products that go into an endless list of items Americans count on every day. Pipeline integrity managers like Plains’ Leslie Fangue work to ensure that everything flows as planned. Leslie and her counterparts throughout the industry analyze operations and complex data gathered from inspections to identify and address anything that could affect a pipeline’s health as quickly as possible.

“I really connected with the idea of integrity, which is all about keeping the oil and gas inside the pipes, where it belongs,” explains Leslie, who was drawn into the midstream integrity specialty during a college internship on her way to a civil engineering degree. “I get to be directly involved with solving problems and managing risks that protect people and the environment. I feel like I’m doing the right thing every day.”

Like roads, bridges and all other kinds of infrastructure, pipelines may change over time. Pipeline facilities include an assortment of components such as pumps, sumps, compressors, meters, tanks and station piping – each of which is inspected using different technologies and techniques. For example, station pipes can be inspected using a technology called guided wave. This involves strapping a tool affixed to a collar around a section of pipe and using ultrasonic waves to detect changes in wall thickness – up to 30 feet in either direction. As the ultrasonic waves travel down the pipe, anomalies are detected, allowing operators to know where to make repairs.

For decades, mainline pipelines have been inspected using in-line tools known as “pigs,” so-called because of the squealing sound they make when moving through pipe. Today, “smart pigs” fitted with an array of high-tech sensors can detect conditions that could affect pipeline integrity, such as metal loss, changes in wall thickness, dents, gouges and cracking. Using onboard GPS, they can identify the location of each anomaly and tag it so that crews can quickly find the right spot for further analysis and repairs.

“Across the entire industry, we’re always working for continuous improvement,” Leslie says. “[P]ipelines are one of the safest ways to transport crude oil and natural gas, especially across great distances … API has a Pipeline Integrity Group that gives us a great forum for sharing best practices, improving industry standards and making sure all operators are on board. Most companies like ours are working hard to go above and beyond regulatory requirements.”

As the 99.999 percent safety statistic shows, they’re doing an excellent job – aided by innovative uses of technology and a commitment to safety.

Energy Is Powering Environmental Progress

Using advanced technologies, natural gas and oil are produced more cleanly and with a smaller environmental footprint. Companies are focused on reducing emissions of methane during production while refineries are producing cleaner fuels.

- Leading Emissions Reductions

- Empowering Renewable Energies

- Developing Cleaner Fuels

- Partnering To Advance Environmental Goals

The High-Tech Approach To Environmental Stewardship

Colleen Faber

Colleen Faber

Environmental Health & Safety Supervisor, Anadarko Petroleum – Wyoming

“Any reduction in our impacts is as good for the industry as it is for the environment, for our communities, and for our own families.”

Today’s natural gas and oil companies are committed to safely developing the energy Americans use every day while also protecting the environment.

A health, safety and environment senior staff representative for Anadarko Petroleum, Colleen and environmental professionals like her at other companies across the natural gas and oil industry work to ensure that industry’s environmental progress continues – built on technology, innovation and ever-improving industry standards and best practices.

Colleen has a degree in agronomy from Montana State University, and she has dedicated her career to safe land use and environmental stewardship. Since she began working at Anadarko in 2004, industry has come a long way.

Engineering innovations like directional drilling are game changers in industry’s effort to limit its environmental impacts. “A single horizontal well can take the place of 10 vertical wells,” Colleen says. “This means less air emissions, less water usage and disposal, and a much smaller surface footprint to produce just as much oil and natural gas.”

Technology and data are also integral across every aspect of oil and natural gas development. “Before any kind of development begins we use geographic information systems data to vet locations, so we can evaluate risks and make the best possible selection,” she says. “Once we pick a location, we do extensive monitoring at the surface to understand the vegetation and soil, so we know exactly how to restore the land once it’s time to shrink our footprint.”

It takes about four to eight weeks to set up and perform a horizontal drilling and fracking operation. Once these activities are completed and the wells are flowing, the heavy equipment is removed and the land around the site pad is restored to its former state. All that remains on the pad are the well heads, valves, flow lines and storage tanks, which take up a fraction of the site’s original footprint.

“Improved practices during drilling and fracking make a significant difference,” she says. “By using surface pipelines to bring in water during drilling and fracking, along with remote telemetry that lets us monitor everything happening at the well sites without having to make daily visits, we’ve made huge reductions in vehicle traffic. This makes our operations safer and better for the environment, for wildlife and for communities.”

While oil and gas companies are busy developing energy from natural resources, they’re also partnering with universities and other facilities to support research and development that continues to move the industry’s environmental progress forward.

“Anadarko was the University of Wyoming’s Research Partner of the Year in 2015,” Colleen says with pride. “Investing in engineering innovations and new technologies is a win-win proposition. We may spend more up-front, but any reduction in our impacts is as good for the industry as it is for the environment, for our communities, and for our own families.”

Positive Change Through Leadership, Technology

Protecting The Environment Is A Core Industry Value.

The communities in which our companies operate expect that we will work to protect the air and water, that we will strive for the smallest possible footprint and that we will carefully restore areas when work is completed. Environmental stewardship is essential to sound corporate conduct. We’re committed to safely and responsibly supplying Americans with the energy they use every day because they’re our neighbors, and these are our communities, too.

Our industry invests in ongoing research into new technologies and other practices for cleaner, more efficient operations. Government data show this commitment has worked. Greenhouse gases have been greatly reduced, cleaner-burning fuels have helped improve air quality and our stewardship of valuable resources, such as water and surface spaces, has grown.

Since 2005, carbon dioxide emissions from power generation have decreased 25 percent.

- By 2030, power plant CO2 emissions could drop as much as 30 percent from 2005 levels

- Fuel switching to natural gas is responsible for the majority of power plant emissions reductions

- CO2 emissions from energy use across the entire economy are at the lowest levels in nearly 25 years

In our latest commitment to environmental performance, we launched The Environmental Partnership, whose participants will work together to further reduce emissions from natural gas development. The partnership also is designed to identify additional opportunities for action on other environmental issues in the future

Bottom line: The natural gas and oil industry will continue advancing environmental performance through innovative research, technology and operational practices.

Greater use of clean, reliable, affordable natural gas is driving significant environmental improvements. The United States is leading the world in CO2 emissions reductions because of abundant domestic natural gas and its use across our economy.

Growing use of natural gas as a fuel for electricity generation has helped lower emissions of carbon dioxide from the power sector to their lowest point in nearly three decades. By 2030, these emissions could drop as much as 30 percent from 2005 levels, primarily as a result of continued fuel switching to natural gas for generating power.

Methane Emissions Down by 16.3%

Between 1990-2015.

Natural Gas Production Up by 52%

Between 1990-2015.

Natural gas is also the essential partner to intermittent renewable energy sources, providing reliable fuel for power generation when the other power sources are unavailable. At the same time, natural gas goes into the production of wind turbine blades and photovoltaic cells – meaning that as more renewable power generation comes online, natural gas’ role will grow, too.

Industry continues to reduce its own emissions. While natural gas production rose nearly 52 percent between 1990 and 2015, emissions of methane from that production declined 16.3 percent. This is primarily because of industry investments in better, more efficient equipment, leak detection measures and other mitigating technologies.

The Environmental Partnership is industry’s voluntary commitment to continuous improvement in environmental performance, with its first initiative focused on taking actions to reduce emissions associated with natural gas and oil production.

The Environmental Partnership’s mission is continuous improvement of the natural gas and oil industry’s environmental performance. Program highlights:

- 27 participating companies

- Reducing methane and other emissions from onshore natural gas production

- Incorporating new technology and best practices

- Reporting and tracking progress

- Sharing data and knowledge

Initially, participating companies are focused on reducing methane emissions from onshore natural gas operations, because EPA identified these operations as a leading source of those emissions.

The foundational principles of the partnership include, first, a commitment to take action and to put technology and innovation to work to further cut methane emissions. Second, participants have agreed to share scientific data, to learn together and to expand what is known about emissions and effective emissions-cutting technologies and programs. The third founding principle, underlying the other two, is collaboration, a commitment to create a united industry effort to achieve emissions reduction goals.

The broader goal is steady environmental progress, which is why participants are committed to annual reporting, which will track that progress and help guide the program in the future. The partnership is adaptable, so that cooperation to reduce emissions may help tackle other important issues in the years ahead.

We have been able to produce more natural gas while also lowering emissions. But rather than rest on these accomplishments, this industry is seeking to build on them. The Environmental Partnership will help America’s natural gas and oil industry share goals, technologies and best practices that will make our environmental performance even stronger.” – Mark Berg, Pioneer Natural ResourcesEnvironmental Enhancements

Industry’s commitment to the environment is backed by hundreds of billions in investments: in technologies to reduce emissions during production, to improve air quality at refineries, to support ongoing environmental research and development and to make cleaner fuels for U.S. cars and trucks.

Cleaner fuels used in today’s more efficient vehicles are helping reduce pollutants in tailpipe emissions. Overall, new cars, trucks, SUVs and heavy-duty trucks and buses run about 99 percent cleaner than models produced in 1970, according to EPA. These helped reduce U.S. air pollution by 73 percent between 1970 and 2016, even as vehicle miles traveled increased 190 percent and the economy grew 253 percent.

The industry also is researching zero- and low-carbon technologies in support of substitute and less carbon-intensive fuels and other energy technologies. Investments totaled nearly $90 billion from 2000 to 2014 – almost as much as the rest of U.S.-based private industries combined. Our companies are investing in wind, solar, biofuels, geothermal and landfill digester gas. Since 2000, the industry accounted for $1 out of every $6 spent on non-hydrocarbon technologies.

Between 1990 and 2016, industry has invested more than $339 billion on environmental enhancements.

- Improved environmental performance: Fuels, operations, facilities

- Focus: Technologies, research & development $1,045 for every person in U.S.

- Includes $166 billion spent by U.S. refiners

Our industry is meeting the country’s energy needs while minimizing our environmental footprint. U.S. natural gas production reached an all-time high in 2015 – more than 27 trillion cubic feet – while crude oil production reached 3.4 billion barrels, output not seen in more than four and a half decades. At the same time, new technologies and more efficient operational practices shrank industry’s surface presence and reduced its use of freshwater. In 2015, nearly 77 percent of the most prolific U.S. wells – those producing more than 400 barrels of oil per day – were horizontally drilled, according to the U.S. Energy Information Administration (EIA) – meaning that multiple laterals can go out from a single vertical well, reducing the surface footprint by as much as 90 percent. Meanwhile, new innovations enable the use and reuse of many kinds of water in operations – including brackish water, produced water and municipal water of varying qualities. These uses, along with advances in hydraulic fracturing fluid chemistry and treatment, cut freshwater requirements, reducing truck volumes, associated noise and road wear and tear. This is a smart, maintainable water use and reuse cycle that can be repeated during natural gas and oil production. In Pennsylvania, for example, industry now recycles more than 90 percent of the wastewater produced from exploration and production activities. Accomplishments like this are becoming increasingly common – as is the repurposing of treated produced water for additional beneficial uses, such as in cooling towers at power plants and in range land restoration.

Pursuing Environmental Performance With Passion

Lola Owolabi

Lola Owolabi

Environmental Engineer, Phillips66 – CA

“We take our impact on the environment, and our responsibility for operating safely, very seriously.”

As an Environmental Engineer at Phillips 66’s Los Angeles Refinery, Lola Owolabi is an expert on air – clean air and keeping it that way. She manages compliance under the refinery’s Title V operating permit, as well as the facility’s flares program. Both roles help ensure that the refinery’s air emissions are within or well below regulatory levels.

“I’m passionate about driving environmental compliance,” Lola says. “Right now, my expertise is in air, but my goal is to learn more about water and waste programs. Eventually, I hope to be in a leadership role as an environmental manager.”

Lola is one of a number of environmental experts working for natural gas and oil companies. Her zeal for environmental progress reflects the natural gas and oil industry’s broader commitment to protecting the air and water by enhancing the environmental performance of operations, products and facilities, such as P66’s L.A. refinery.

Born in Nigeria, Lola moved to the United States with her family as a teenager because her parents wanted her and her brother to attend college in the U.S. In 2008, Lola graduated with a chemical engineering degree and started working for ConocoPhillips. When the company split its upstream and downstream operations in 2011, Lola stayed with its downstream side, now known as Phillips 66. She has since parlayed her interest in environmental stewardship into a master’s degree in environmental engineering, which she completed in 2014.

For Lola, the best part of her job is feeling like a valuable part of a team that’s making a difference. “I like knowing my contributions matter,” she says.

“For instance, we recently needed to make repairs to a roof ladder on one of our storage tanks, and I was able to successfully petition the Air Quality Management District to let us make the repairs without taking the tank out of service.”

It was an important achievement. Taking a storage tank out of service means using degassing equipment – a source of air emissions – and it’s a costly process, she says. Her work showed that a major industrial facility like a refinery can conduct important operations and protect the environment in a way that’s cost-effective.

“One of the highlights of my career so far was working with a team to reduce flare emissions from planned maintenance work at our Carson, California, facility,” she says. Using an innovative, caustic scrubbing technology, the team significantly reduced flare emissions and set a new standard for Phillips 66.

“We were able to minimize our environmental footprint – and do the right thing for the local community,” she says. For their efforts, the Carson project team earned a Phillips 66 Golden Shield Award, the company’s highest recognition for outstanding commitment to the community by delivering best-in-class environmental performance.”

Lola is proud of the industry’s continuous investments in improved safety and environmental performance. “Our industry is highly regulated,” she says. “We take our impact on the environment, and our responsibility for operating safely, very seriously.”

Energy Is Powering The Economy

Natural gas and oil support jobs across the breadth of the U.S. economy and in all 50 states, generating tax revenues for governments at all levels that help individual communities. In turn, increased American energy production benefits consumers, strengthens the power grid, supports U.S. trade and increases our nation’s security.

- Creating Jobs, Income and Opportunity

- Boosting National Economic Growth

- Benefiting Consumers

- Fostering Energy Security

The Opportunity For A Career And Prosperity

Carmen Segivia

Carmen Segivia

Advanced IT Business Analyst, Marathon Oil – Texas

“I come from an immigrant family that started with nothing … Me? I’m not starting from zero. I was given an opportunity.”

Advanced IT Business Analyst Carmen Segovia is living the American dream. At 25, she works in both her chosen field and her chosen industry, for a company – Marathon Oil – that has been a wellspring of opportunity since her undergraduate days at the University of Houston (UH). A first-generation Mexican American, Carmen’s achievements are the product of her own ambition and hard work. Hers is a story being repeated at companies across the natural gas and oil industry as more women and minorities join an increasingly diverse workforce. Neither of her parents went to college, and as the oldest of four children, Carmen had to blaze her own trail with scant practical guidance or financial support. Carmen’s introduction to Marathon Oil came while she was pursuing a bachelor’s degree in management information systems at UH. Marathon sponsors the Diversity Scholarship Fund. In her sophomore year, Carmen applied for the scholarship, as well as an internship at Marathon. “I really wanted the scholarship,” she says. “My dad always pushed college, so it was never a question of whether I would go. The question was how I would pay for it.” Carmen put her best foot forward when she visited Marathon Oil headquarters for her scholarship interview. She was ecstatic two months later when she learned that she’d won the scholarship – and a paid internship. “Mind-blown” is the term she used. “I was born and raised in Houston, and all you hear is how great it is to work for oil and gas. I always wanted to be part of it. I was so lucky how things fell into place.” Carmen’s scholarship lasted through her remaining two years at UH. When her first internship ended, she was offered another one. Once she graduated, Marathon offered Carmen a full-time job. Five years later, Carmen’s ambitions continue to grow. A natural leader, she’s thinking about pursuing an MBA, and hopes to her work her way up to Marathon’s C-suite. “There’s definitely room to grow here,” she says. “The company is always encouraging various training and development opportunities, and my supervisor fully supports the idea of me going back to school.” As an Hispanic, Carmen is part of industry’s active efforts to tap talents and contributions from all quarters of society by developing a workforce that better reflects the country’s growing diversity. Carmen’s story also is about more industry opportunities for women. A 2016 report estimates minorities and women will occupy tens of thousands of industry jobs by 2035. When thinking about her career today, what Carmen appreciates most is the opportunity the oil and natural gas industry provides. “I come from an immigrant family that started with nothing, and had to build from the ground up,” she says. “Me? I’m not starting from zero. I was given an opportunity – one that has benefitted me for several years now, and will continue doing so in the future.”

Fueling Growth And Opportunity

The United States And The World Are Powered By Natural Gas And Oil.

Access to affordable, reliable energy enables the modern standard of living Americans enjoy today. For the U.S. economy, natural gas and oil play leading roles. Together, they supplied about two-thirds of the energy Americans used in 2016, according to the U.S. Energy Information Administration (EIA), and EIA estimates they will account for nearly 70 percent of the country’s energy use in 2050.

That’s energy for transportation to and from work, across the country and around the world, and energy to run factories and businesses. It’s energy for manufacturing the goods that make lives modern, convenient, healthier and safer. Energy fuels the economy

The uses of natural gas and oil are all around us – in fuels for transportation and manufacturing, in the chemistry that go into countless consumer products Americans use every day, in advanced life-saving medical devices and in inventions only dreamed of years ago. The ubiquity of natural gas and oil and the demand for the products that come from them are the reason they drive economic growth. That growth, in turn, drives the need for more energy, making our industry a growth point itself.

The natural gas and oil industry supports 10.3 million jobs today – a half-million more than it supported in 2011. And, industry’s long supply chain reaches all 50 states – service companies, contractors, vendors, equipment manufacturers, fabricators of steel pipe and many more. There also are indirect jobs in businesses that serve the needs of direct industry employees, jobs that might not exist in the same quantity or in specific locations were it not for industry’s presence.

10.3 Million

American Jobs

Every job our industry supports – direct, indirect and induced – represents a paycheck, the economic livelihood of an individual American and/or a U.S. household. Jobs sustain, empower and offer promise. A job pays for the necessities of life, helps provide access to health care and provides the avenue to personal aspirations. Natural gas and oil industry jobs do all of these things – while the products industry supports help power an expanding economy.

Consumer And Business SavingsAmerica’s energy abundance has helped lower energy costs for consumers, which boosts the broader economy as U.S. households have more to spend on things besides energy. Between 2008 – about the time the U.S. energy renaissance started – and 2014, average annual energy costs per household dropped 14 percent, reducing Americans’ overall living costs and increasing disposable income. According to one study, abundant shale energy increased household disposable income by $1,337 in 2015. Meanwhile, growing U.S. crude oil production put downward pressure on global crude prices, ultimately saving U.S. motorists, on average, about $550 at the gasoline pump in 2015 compared with 2014.

Likewise, American energy has lowered costs for businesses and industry, spurring the manufacturing sector’s renaissance and bringing a number of manufacturers back to the U.S. from overseas. Producers of steel, chemicals, plastics and other products have benefited from lower costs for power and feedstocks thanks to abundant domestic natural gas and oil. U.S. industrial natural gas and electricity costs are significantly lower than those of most of our foreign competitors. China’s manufacturing cost advantage over the U.S. shrank from 14 percent in 2004 to an insignificant 1 percent in 2016. That’s a direct boost to the global competitiveness of U.S. companies.

Electricity is essential for a 21st-century economy, and natural gas is becoming the marketplace’s choice for fueling power generation. In 2016, natural gas was the leading fuel for total U.S. power generation across all sectors (electric, commercial and industrial), chiefly because it is clean, abundant and reliable. It was on track to be the leading fuel again in 2017.58 Natural gas-fueled generation also provides important attributes – including dispatchability, ramp rates and frequency response – that ensure the reliability and resilience of the modern electric grid. These attributes also make natural gas an essential, reliable partner for intermittent fuel sources like wind and solar.

Marty Durbin, API’s executive vice president and chief strategy officer, recently testified during a hearing on electricity grid reliability held by the House Energy and Commerce Committee’s energy subcommittee:

“The increased use of natural gas in electric power generation has not only enhanced the reliability of the overall system, but it has also provided significant environmental and consumer benefits. The abundance, affordability, low-emissions profile and flexibility of natural gas and natural gas-fired generating units make natural gas a fuel of choice.”

Markets are driving the selection of natural gas to fuel power generation. Since 2000, demand for natural gas for power generation has almost doubled. While natural gas-fueled generation is providing reliability and resilience to the electric grid, it also has lowered costs for consumers. According to one study, U.S. consumers could save an estimated $100 billion – or $655 per household – by 2040 from the increased use of natural gas throughout the economy, including power generation. Natural gas supported more than 4 million jobs across the U.S. in 2015, from production to end uses such as manufacturing. The number is expected to rise to 6 million jobs by 2040. The supply chain for natural gas – suppliers, vendors, contractors – supported 3 percent of the U.S. economy in 2015, including direct, indirect and induced activities and jobs.

Natural Gas Benefits

By 2040, consumers across the country could save an estimated $100 billion, or $655 per household, from the increased use of natural gas throughout our economy – from manufacturing to generating affordable electricity.

In 2015, the natural gas supply chain supported 3 percent of the U.S. economy, including direct, indirect and induced activities and jobs associated with natural gas.

In 2015, natural gas supported more than 4 million jobs across the country from production to end uses like manufacturing. That number is expected to rise to 6 million jobs by 2040.

America’s energy renaissance is making it a leading energy exporter to the world. The International Energy Agency (IEA) projects that U.S. shale energy will push combined natural gas and oil production to a level 50 percent higher than any other country has ever managed, which will help support exports. In its “Gas 2017” report, IEA projects that by 2022 the U.S. could be the global leader in exporting liquefied natural gas (LNG), surpassing Australia and Qatar.

Energy exports serve multiple U.S. interests. Exports help spur domestic production. They strengthen the United States’ trading posture and allow the U.S. to provide energy to friends and allies around the world. U.S. LNG exports by vessel are surging, growing from about 184 billion cubic feet (bcf) in 2016 to nearly 410 bcf through August 2017. U.S. crude oil exports have grown from 48 million barrels in 2013 to more than 217 million barrels through August 2017. Growing U.S. LNG exports could add up to $73 billion to the U.S. economy by 2040 and support between 220,000 and 452,000 additional American jobs.

The United States’ emergence as a leading energy exporter is supported by mutually beneficial trade agreements. For example, the North American Free Trade Agreement (NAFTA) guarantees access to North American markets, which benefits the U.S., Canada and Mexico. NAFTA fosters market efficiencies that have helped bring more affordable energy to consumers in all three countries.

Trade of U.S. energy and energy products under NAFTA helps support U.S. jobs. In all, more than 80 U.S. refineries imported crude oil from either Canada or Mexico in 2016, turning that crude into products Americans use every day.

Refineries mostly in the Midwest and Gulf regions, supporting thousands of jobs, are configured to process heavy crudes from Canada and Mexico.

Thanks to free trade, Mexico and Canada are the top importers of U.S. natural gas and oil and refined products.

The U.S. and Mexican natural gas markets also are becoming more physically interconnected. Pipeline capacity for natural gas exports from the U.S. to Mexico has rapidly expanded in the past few years and currently stands at 7.3 billion cubic feet per day – which is expected to nearly double in the next three years. Given the interconnected markets of the U.S., Canada and Mexico, North American energy security is at its strongest in decades.

Whether it’s management, finance, engineering, chemistry or something else entirely, industry employs experts in a wide-ranging number of professional fields, across a range of job sectors in every state. These are good-paying jobs – jobs with a future because natural gas and oil will continue to power the world.

- 1.9 million new job opportunities by 2035

- $50,000 Average industry pay higher than U.S. average

- STEM: Bachelor’s degree in science, technology, engineering or mathematics nearly doubles likelihood of working in industry

- 57 percent of industry’s new job opportunities will be in blue-collar occupations

The RAND Corporation found that almost without exception – across education levels, degree majors, gender and race/ethnicity groups and occupation types – men and women working in our industry earn more than those working in other sectors. Based on 2016 average annual wage data from the Bureau of Labor Statistics, the average pay in the oil and gas industry is nearly $50,000 higher than the U.S. average. Ours is a job-growth industry, with one report estimating the natural gas and oil and petrochemicals industries could create 1.9 million new job opportunities by 2035. There will be opportunities for women and minorities. There will be opportunities for people with degrees in science, technology, engineering and mathematics (STEM) – degree fields with great potential for advancement. It’s the reason industry is focused on supporting STEM education. (For more, see Communities)

Infrastructure Today And TomorrowThe economic gains and energy benefits produced by our natural gas and oil resurgence need policy support to continue and expand. Even now some parts of the U.S. don’t have the same access to energy and its benefits as others, chiefly because of infrastructure constraints. The country needs more pipelines, storage, processing, rail and maritime infrastructure to provide that access.

The effects of insufficient infrastructure are acutely apparent in New England, where residents paid 50 percent more for electricity than the national average in 2016, while industrial users paid almost 80 percent more for electricity than the national average. Both percentages reflect costs associated with constrained access to natural gas as a fuel for power generation. Natural gas provides nearly 50 percent of the region’s fuel, yet significant physical constraints limit the amount of natural gas available to generators at certain times of the year. And failure to expand natural gas and electricity infrastructure in New England could cost the region’s households and businesses an estimated $5.4 billion in higher energy costs and more than 167,000 private-sector and construction jobs between 2016 and 2020.

Infrastructure is the essential link between America’s energy wealth and every energy user. Building pipelines and storage terminals and revitalizing our ports could be a leading catalyst for economic growth. Between 2017 and 2035, infrastructure is projected to support an average of up to 1.4 million American jobs annually, not only within states where infrastructure development occurs but across all states because of extensive indirect and induced labor impacts.

New England Residential Consumers Paid 50% More For Electricity

New England Industrial Consumers Paid 79% More For Electricity

Compared to national average for residential and industrial users in 2016

Failure to expand natural gas and electricity infrastructure in New England could cost the region’s households and businesses an estimated $5.4 billion in higher energy costs and more than 167,000 private-sector and construction jobs between 2016 and 2020.

Adding infrastructure also is important to sustained, long-term economic growth and our nation’s ability to harness its natural gas and oil potential. By not adding infrastructure capacity or developing our resources, we may fail to capture benefits like those the U.S. energy renaissance has brought to every American.

This is explained in a recent study that estimated negative economic impacts if the U.S. stopped building infrastructure and stopped new development of certain energies, including natural gas and oil. Job losses could be significant, impacting energy-producing states the most, while the broader economy could be harmed by increased costs for production and transportation of goods, with the cumulative gross domestic product loss by 2040 totaling $11.8 trillion. According to the study, the average U.S. household could see its costs jump $4,552 by 2040 due to higher costs for transportation fuel, electricity, home heating and goods and services. The study concludes that electricity prices alone could increase an average of 56.4 percent.

The United States’ renaissance in natural gas and oil production has provided a game-changing opportunity for our country to secure its economic future – as well as its broader security. Long-term U.S. energy policy should be forwardlooking, recognizing the essential, powerful support natural gas and oil have provided and can continue to provide to the national economy as well as the prosperity of individual Americans and their families.

Energy Is Powering Manufacturing

Natural gas and oil are used in everyday products too numerous to count – as well as in cutting-edge technologies and inventions that improve Americans’ health; support longer, more enjoyable lives; and boost their standard of living.

- Supporting Modern Lifestyles

- Safer Vehicles

- Energy for Advanced Technologies

Energy For Quality Of Life

Bergan Flannigan

Bergan Flannigan

Retired U.S. Army Captain – New York

“You’ve got to get up and get on with your life… I’m proud to have served my country. I’ve got no regrets.”

Life can change in an instant. It did for U.S. Army Capt. Bergan Flannigan in 2010. One moment she was leading a foot patrol in Kandahar, Afghanistan. The next she was on the ground, a high-pitched ringing in her ears and her right leg shattered by a roadside bomb.

What Bergan thought would be a long military career was cut short, in an instant. After numerous surgeries and two years at Walter Reed National Military Medical Center, she’s now retired, back in her hometown of Plattsburgh, New York, and caring for her 3-year-old daughter, Willow.

From the moment Bergan wakes up in the morning until she goes to bed at night, she wears a prosthetic leg that’s a melding of biomedical engineering, artificial intelligence and petroleumbased materials. Modern prosthetics like Bergan’s provide better mobility and more comfort than ever before for about 2 million Americans living their lives after losing a limb. Bergen started wearing her prosthetic when she was pregnant with Willow. “I figured I’d need full-time mobility as a mom, so I might as well get used to it,” she says. Which she has done. In fact, being a mom gives Bergan extra incentive to go about business as usual.

“I used to feel self-conscious about people staring at my leg, so I’d avoid social situations,” she says. “But I’ve had to get over that because I don’t want Willow to miss out on anything.” Bergan’s daily routine includes about two hours of gym training. “I used to be all about cardio, but I’ve made some adjustments.” Now she’s an avid weightlifter and is game to explore new physical endeavors. Last winter she tried skeleton sledding, which is similar to riding a luge, but with the rider lying face down and head first.

Losing a limb is life-changing, but Bergan proves it doesn’t have to be life-ending. Her prosthetic plays a big part in that. Durable, lightweight resins derived from natural gas and oil are integral in the new generation of “active prostheses” that can mimic human characteristics such as flexibility, grip, strength and surface friction.

In the seven years since Bergan lost her leg, she has had several different prosthetics and dozens of different sockets – the component that encases the residual limb. It’s by far the most important feature for an amputee’s comfort and mobility. Bergen’s current, double-walled socket was designed and fitted by prosthetist Jeff Erenstone, owner of Create O&P in Lake Placid, New York, which uses 3-D printing technology to build prosthetics, reducing the time it takes to build and customize a socket from a few weeks to a few hours. Prosthetists are assisted in their craft by a new generation of thermoplastic urethane (TPU), a soft flexible material that is also strong and durable and derived from petroleum. Soon it will be possible to make prosthetics with different densities — soft in the fleshy areas but more rigid in the center where the bone would be — to better replicate the feel of a real limb.

Create O&P also makes custom prosthetic covers that encase the prosthetic’s metal pipe. These can be made in a wide array of colors and patterns – and even imprinted with a tattoo – to help users feel more emotionally connected to the device. “I have Rosie the Riveter on mine,” Bergen says. “She’s a symbol of women’s strength, and I just think she’s cool.”

Strength is something Bergan and the iconic riveter have in common. When people ask about dealing with adversity, she points to inner determination. “It’s hard, and it’s going to be hard,” she says, “but it comes down to you. You’ve got to get up and get on with your life. In spite of what happened to me, I’m proud to have served my country. I’ve got no regrets.”

Creating Products Of Everyday Life

Other Than Water There Are Few Substances On Earth That We Count On More Than Natural Gas And Oil.

A few years ago, the Manhattan Institute’s Robert Bryce wrote: “If petroleum didn’t exist, we’d have to invent it. Nothing else comes close to oil when it comes to energy density, ease of handling, flexibility, convenience, cost, or scale. Bryce was spot on. Natural gas and oil are packed with energy; they’re portable and storable. The adaptable properties of natural gas and oil, for the fuels and products we use every single day, make them a necessity for modern life.

Very few aspects of modern life aren’t touched in some way by natural gas and oil. Thousands of products made from natural gas and oil make life healthier, safer, more comfortable and more enjoyable. They help save time for the things we want to do. They support creativity, help us manage our environment and think beyond ourselves. Their hydrogen and carbon molecules provide the building blocks for thousands of products and materials that weren’t available to Americans 100, 50 or even 25 years ago.

In terms of products that are essential to modern living, natural gas and oil play important roles in a number of areas – medicine, health care, transportation technologies, safety, clothing, equipment for first responders and so many more. In all of these uses associated with natural gas and oil, the greater good is served.

This is especially true in the medical field. The products made from natural gas and oil – such as artificial heart valves and acrylic lenses – are strong and durable, yet lightweight with the ability to be formed into any shape and less likely to pose a rejection risk. This makes them very useful in medical supplies such as sterile gloves, IV lines and more.

We enjoy a level of mobility that would have been impossible 100 years ago. From planes to cars to buses to bikes, we are able to navigate our world more quickly and efficiently than ever before, with help from natural gas and oil. Motor vehicles, no matter the power source, are safer, lighter, sleeker and faster because of petroleum- and natural gasbased fibers, compounds and adhesives used to manufacture and maintain them. We rely on seat belts and air bags, made with the help of natural gas and oil, to keep us safe in vehicle emergencies. Other materials and fabrics manufactured from natural gas and oil – durable, yet lightweight and flexible – help protect first responders, who in turn protect the rest of us.

All of this is possible because of the seemingly endless ways scientists are able to manipulate hydrocarbon molecules to create fabrics that have the qualities people need and want for multitasking lifestyles. As these types of products become more popular, not only will the apparel of tomorrow look good and be more comfortable, it may alert us to medical emergencies, help us train more safely and more efficiently, and ultimately take its place as part of the digital universe alongside our smartphones, fitness trackers, tablets and laptops.

The catalogue of products like these that reach each part of everyday life is voluminous. Natural gas and oil also support creativity and modern communications. From the pottery made during Egypt’s first dynasty about 8,000 years ago, to the 15th-century introduction of oil paints to the invention of photography in the early 19th-century to the advent of recorded sound and motion pictures at the beginning of the 20th-century, technology assisted by energy has advanced artistic expression.

The following content illustrates the positive ways natural gas and oil impact our lives.

Energy Is Everything

From health to transportation safety to favorite pastimes and much more, natural gas and oil are involved in the products that make Americans’ lives modern, healthier and more comfortable.

Up to 1.5 million Americans suffer from a narrowing of the heart’s aortic valve.98 For many, a stent offers the best remedy. The most advanced stents are sheathed in a thin, flexible layer of polyethylene terephthalate, a petroleum product similar to polyester.

Specially designed lenses made from acrylic, which is made from petroleum, are used to treat cataracts, which afflict 24.4 million Americans over the age of 40. The lens mimics the natural transparency and flexibility of an organic lens and, according to one clinical study, improves uncorrected distance vision to 20/40 or better in 94 percent of patients.

Plastics made from natural gas and oil are used for intravenous lines and bags, sterile gloves, anesthesia masks, catheters and more.

Made from nylon, air bags contain the first mass-produced synthetic fabric, which is made with chemicals found in crude oil. This safety feature is estimated to reduce the risk of dying in a direct, frontal car crash by as much as 30 percent, according to the National Highway Traffic Safety Administration. Almost 40,000 lives were saved by air bags during the first 25 years as required equipment in U.S cars, according to NHTSA.

Belts – made from polyester, a strong, durable and flexible fiber that began as natural gas and crude oil – have been standard equipment for decades. According to the Centers for Disease Control and Prevention, using seat belts reduces the risk of death by 45 percent and serious injury by 50 percent.

More than 8 percent or 332 pounds of a new car’s weight in 2015 came from fossil fuel-derived materials, up from less than 20 pounds in 1960. These materials actually reduce the overall weight of cars and trucks by replacing heavier materials, which has helped reduce U.S. air pollutants by 73 percent between 1970 and 2016, even as vehicle miles traveled have increased by 190 percent.

Printers extrude heated plastic, metal or other materials, layer upon layer, to create a three-dimensional object. Some of the most common printing filaments in these devices use plastics derived from natural gas and oil. Super computers and 3-D printing were at the heart of a 2017 project during which a team of computer engineers distilled the “artistic DNA” from a painting by Rembrandt to create an “original” of the Dutch master who died almost 350 years ago. A computer-assisted 3-D printer created an original 13-layer painting with more than 148 million pixels. This type of computing takes enormous amounts of energy. The typical super computer uses about 4 megawatts of power an hour, or 40 times that of the average American household – electricity increasingly generated by natural gas.

Clothing manufacturers create innovative fibers that provide more than a fashion statement. One line of women’s sportswear made from a unique blend of polyester, nylon and elastane, all derived from petroleum, is antimicrobial, extremely elastic and moisture-wicking. It also relays, in real time, the wearer’s vital signs gathered from several sensors embedded in the fabric, which includes a magnetometer, a gyrometer and several accelerometers. The clothing reports back to a Bluetooth radio that communicates the data to a smartphone.

Much of the fire protection gear used by the more than 1.1 million firefighters in the United States is made from advanced fabrics and fibers that come from natural gas and oil, including Kevlar and Nomex, which provide flexible fire- and heat-resistant protection.

An astronaut’s space suit has 14 layers of materials, including urethane-coated nylon, Kevlar, spandex and a pressure-restraining Dacron – all synthetic fabrics made from refined petroleum – to keep the wearer safe. Helmets contain plastic made from refined petroleum, 115 and the helmet’s visor is made from polycarbonate, a petroleum-based thermoplastic polymer that also is used to make bulletproof glass in cars.

Carbon fibers and other components derived from oil enhance safety and production, helping workers lift heavy loads. Other exoskeleton technology provides power and torque to joints that reduce the burdens on soldiers carrying gear in the field.

Plastics for bottled water, water-filtering pitchers, water-softening attachments for the shower and many other water-related containers, cups and other devices all are made with natural gas and oil, with processes fueled by natural gas and oil.

Energy fuels technologies that produce clean water. These include one technology that extracts nutrients and pollutants from cow waste to produce water clean enough for the cows to drink, which could help farmers manage their livestock waste. Another system can purify large amounts of water for humans. After Haiti’s 2010 earthquake, 15 of these systems were installed, together purifying 10,000 gallons of water every day.

Ammonia is made from natural gas, and 80 percent of all U.S. ammonia production is used to produce fertilizers. The nitrogen in ammonia is essential for crop growth. Although it varies depending on the crop type, approximately 200 pounds of ammonia are used for every acre of land during crop season.

The first commercial land-based solar cells were developed by ExxonMobil in 1973. New work on solar cells involves development of copolymer resins for photovoltaic cells that form a protective layer between the cells’ electronics and glass.

RP-1 fuel, a derivative of kerosene, is a liquid rocket propellant used by the first-stage boosters of the Saturn V rockets that took Americans to the moon, and is still used to put satellites in orbit with boosters such as the Falcon 9 rocket. About 95 percent of liquid hydrogen, often used for propellant once a vehicle clears the earth’s atmosphere, is made with help from natural gas.

More than 96 percent of all manufactured goods trace back to chemistry, and natural gas and oil provide the feedstocks to make about 99 percent of all petrochemicals in the U.S.

Drones and robots, which can go where humans can’t, are made with carbon fiber-reinforced polymers derived from petroleum, which allows for increased payload and performance.

Many oil-based paints are manufactured from petrochemicals. Solvents that make paint easier to apply and polyurethane resins that help paint dry also are made from petroleum.

Synthetic brushes typically consist of nylon or polyester, both derived from petroleum.

Energy Is Powering Communities

We’re all in this together. Natural gas and oil companies and their employees are invested in supporting and strengthening the towns where they operate – because they live, work and play there, too.

- Setting Standards for Safety

- Investing in Education

- Broadening Industry’s Workforce

- Being Good Neighbors

Working Together And Keeping Our Communities Safe

Jimmie Pavelock

Jimmie Pavelock

Assistant Chief, Glenham Fire Department – New York

“They’re a great contributor… [Chevron] be a long-standing part of the Glenham family.”

At age 16, Jimmie Pavelock already was doing what so many kids want to do when they grow up – working as a firefighter.

Born and raised in the heart of New York’s Hudson River Valley, Jimmie honed his skills as a first responder with fire departments throughout the region and kept them sharp, even as he followed other pursuits. Now a retired police detective, Jimmie’s still fighting fires as assistant chief of the Glenham Fire District in the hamlet of Glenham, New York.

The Glenham Fire District operates out of the Slater Chemical Firehouse, next to what was Texaco’s Research Center, a 153-acre complex that supported the company’s downstream petroleum and energy business. Chevron merged with Texaco in 2001 and ultimately opted to centralize its research and development at facilities elsewhere, yet the company remains connected with the surrounding community – including Jimmie and his fellow first responders.

Over the past several years, Chevron has made financial donations to support critical purchases, including turnout gear – the thermal protective coats, pants, boots and helmets firefighters wear – cold water rescue suits, thermal imaging cameras and emergency medical kits for all of the department’s vehicles.

“The turnout gear alone is huge,” Jimmie says. “We’re a small volunteer department with a limited budget, and this offsets expenses we have related to our building and our equipment. We’d gotten to the point where we didn’t have gear that would be approved for a new firefighter.”

Turnout gear is made of fire-resistant petroleum-based fibers, such as Kevlar, and must be updated every 10 years to pass inspection. A single suit can cost in the neighborhood of $3,000. “It’s a big risk not to have the equipment we need,” Jimmie says. As an FF2 certified firefighter and Level II certified fire inspector, with three in-fire life saves under his belt, Jimmie speaks from experience.

“We handle over 300 calls every year, from basic grass fires, to big structural fires and priority onmedical calls. The community can’t go without this fire department.”

Jimmie says Chevron has partnered with other area organizations in similar ways. “They’re a great contributor,” he says. “They’ll be a longstanding part of the Glenham family.”

Chevron currently is working with the Town of Fishkill, New York, and the larger community on a vision for future development on a former Texaco site, now known as Glenham Mills.

“Chevron holds monthly meetings here at the firehouse,” Jimmie says. “People are eager to see something put on the property, but there are varying opinions about what that should be.” Smiling, he adds, “Personally, I’d like to see a golf course.”

Strengthening The Places We Call Home

The Natural Gas And Oil Industry’s Value To Society Is Much More Than Barrels Of Oil Or Percentage Points Added To Annual Gdp.

Production and economic growth are important. They make our country more secure and provide paychecks for millions of Americans. Yet, nearly two decades into the 21st-century we know that those around us weigh our performance by more than just output. So, as the United States remains the world’s leading natural gas and oil producer and its leading refiner, industry is working safely and responsibly, and engaging with Americans on society’s broader needs and helping develop solutions. For our industry, a big part of corporate responsibility is focusing on the greater good.

Saftety First, Safety AlwaysWe’ve discussed how we’re continually improving the environmental performance of our operations and products, helped by advanced technologies and innovations. We’re also constantly improving standards and recommended practices – the bedrock of safety. API was born as a standardssetting organization nearly a century ago, and establishing operational standards and best practices is a continuing core mission. Since 1924, API has developed nearly 700 standards covering all segments of the industry, all of them working in some way to enhance safety – in operations, equipment, worker training and more.

Take well cementing and other drilling operations. API’s Global Industry Services gathered a cohort of industry engineers, government agency representatives, scientists, academics and non-governmental officials to create the best designs. Pipelines are safer and more durable because pipeline experts assembled by API wrote standards for materials, operating mechanisms and monitoring capabilities. Similarly, refineries are safer and more efficient because of standards written for equipment and complex refining processes.

Each standard is developed through a rigorous process that pulls in experiential and experimental research and that is accredited by the American National Standards Institute. This ensures that relevant expertise, scientific data and a range of viewpoints go into standards that then are thoroughly discussed and reviewed before publication.

Putting Safety First

Industry standards and best practices are designed to protect communities and our own employees. By the numbers:

- 4,130: Number of times state regulations cite API standards

- 430: Number of times federal agencies cite API standards

- 260+: Number of API standards for exploration and production

- 260+: Number of API standards for exploration and production

- 180+: Number of refining safety-related operating standards and work practices

- 41,463: Miles of pipelines inspected in 2015 with “smart pig” technology, to maintain safety

- DOWN 34%: Decline in injury and illness rate for U.S. natural gas and oil industry from 2007-2016136

- 6x: Refinery employees are six times less likely to be injured on job than workers in other manufacturing sectors

More broadly, API has more than 260 exploration and production standards, with 91 specific to offshore operations and 96 referenced in the government’s offshore safety regulations. More than 180 safety-related refinery operating standards and workplace practices have been developed, too.

Standards are a big reason, for example, that virtually all – 99.999 percent – of natural gas and crude oil and petroleum products delivered by pipeline reach their destinations safely. Technologies support standards and best practices. An example is the “smart pigs” that travel inside pipelines, scanning surfaces like a medical MRI, to detect early signs of corrosion, dents, cracks or other issues. In 2015, pipeline operators used smart pigs to inspect more than 41,000 miles of pipelines.

Preparedness also is important. One of the essential considerations surrounding offshore energy production is protecting coastal communities, their commerce, recreation and tourism. The Center for Offshore Safety was created to help offshore operators take a systematic approach to safety through protocols, processes, leadership and training.

Safety and Environmental Management Systems (SEMS) support that approach. Specified in API’s Recommended Practice 75, SEMS help offshore operators reduce the likelihood of incidents and also establish a specific plan to lessen the effects of a potential incident. SEMS are subject to independent, third-party audits that check leadership, training and safety structures. The goal is embedding safety in all aspects of an offshore operation.

One of the best ways we strengthen communities is by providing jobs. Natural gas and oil industry employment means a good-paying job with the chance to grow and advance. Our industry is more than a collection of petroleum engineers and oilfield hands. We’re also mathematicians, chemists, biologists, environmental engineers, civil engineers, geologists, statisticians, computer programmers and more.

Job opportunities in our industry likely will grow over the next couple of decades as our industry expands, requiring more workers, and as Baby Boom generation workers retire. We’re projected to have nearly 1.9 million new job opportunities by 2035. According to an IHS study, women and minorities will account for hundreds of thousands of those openings – more than 700,000 African Americans and Hispanics and 290,000 women through 2035. Millennials, who make up 34 percent of our current workforce, are expected to account for 41 percent of it by 2025.

Millennials’ projected share of workforce by 2025:

Projected share of managerial, business, financial, professional occupations to be held by Millennials by 2025:

- Millennials currently account for 46 percent of all industry employment in unskilled, blue-collar occupations

- Millennials currently account for 42 percent of all industry employment in semi-skilled, blue-collar occupations

These projections signal a great opportunity for our companies to develop a workforce that better reflects America – tapping a broader span of skills, intellect, creativity and perspectives – which will strengthen our industry in the future. Toward that goal our companies are investing in education and other initiatives to help build tomorrow’s workforce. We’re helping build interest in science, technology, engineering and mathematics (STEM) subjects as early as kindergarten and to hold that interest through high school and college. We support STEM summer camps, hands-on laboratories for students, training and curricula for prospective and experienced classroom teachers and more.

The prospects are encouraging. Nearly half of U.S. high school graduates who took the ACT exam expressed STEM interest, and those students outperformed their peers in college readiness. The number of college degrees received in science and engineering disciplines is growing, with a 2015 report finding that 13 of the top 25 jobs for Millennials are in STEM-related fields.

“you don’t have to be a land man or a petroleum engineer. There are other things you can do in the oil and gas industry.” – Supply chain sourcing managerIn Our Communities

We’re committed to the communities where we operate – the places our employees call home. Our companies and their employees help build and improve thriving communities through education, engagement with charitable organizations and other local initiatives.

This commitment is part of why natural gas and oil companies along the Texas-Louisiana Gulf Coast and their employees helped cities and towns meet the severe challenges posed by Hurricane Harvey last year. It started even before the storm made landfall, when refineries safely shut down for the protection of employees and the surrounding areas. Similarly, when it was safe to restart refineries detailed, orderly processes brought them back online.

After the hurricane our companies looked after own employees and then restored fuel supplies for first responders. During recovery, our companies donated more than $32 million to relief efforts, and their employees reached out to those in need – as volunteers or simply as neighbors helping neighbors. After Hurricane Irma struck Florida, our industry’s refinery and supply transportation sectors restored fuel supplies as quickly as possible – again, so that emergency officials could do their work, and then to help Floridians get back on their feet.